When working on a project, every detail, even the most ordinary ones, must be considered to ensure a successful design.

The dimensions of an enclosure matter a lot, and choosing the right material for the job is equally important.

Engineers should think about the operating conditions of the enclosure, as well as the project costs and aesthetic needs.

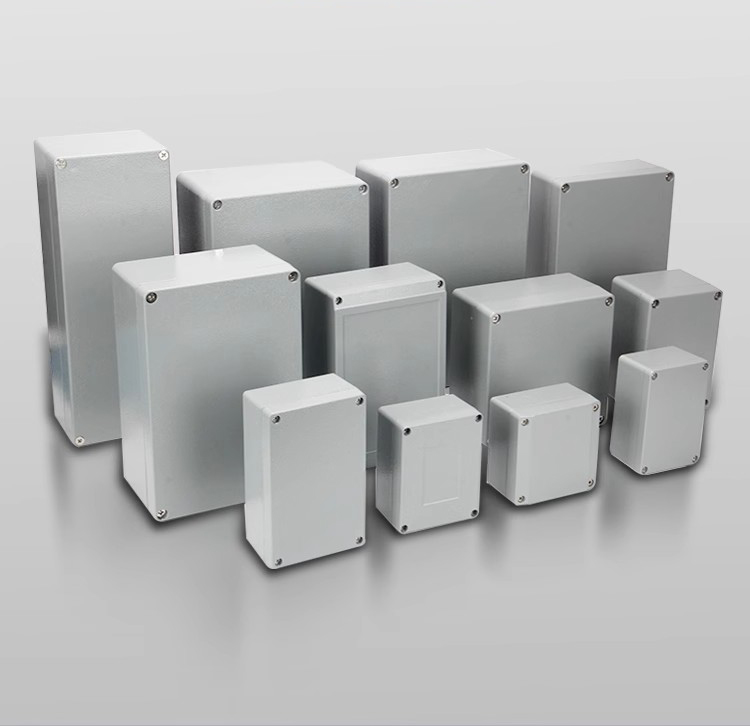

We offer good options in multiple materials, like various metals and plastics. Our most popular enclosures are made of aluminum or plastic (both polycarbonate and ABS).

Many think aluminum is always more durable than plastic, but plastic enclosures can be used in similar industrial and harsh settings too.

While both materials have excellent durability, there are pros and cons to consider when deciding which material and enclosure to pick.

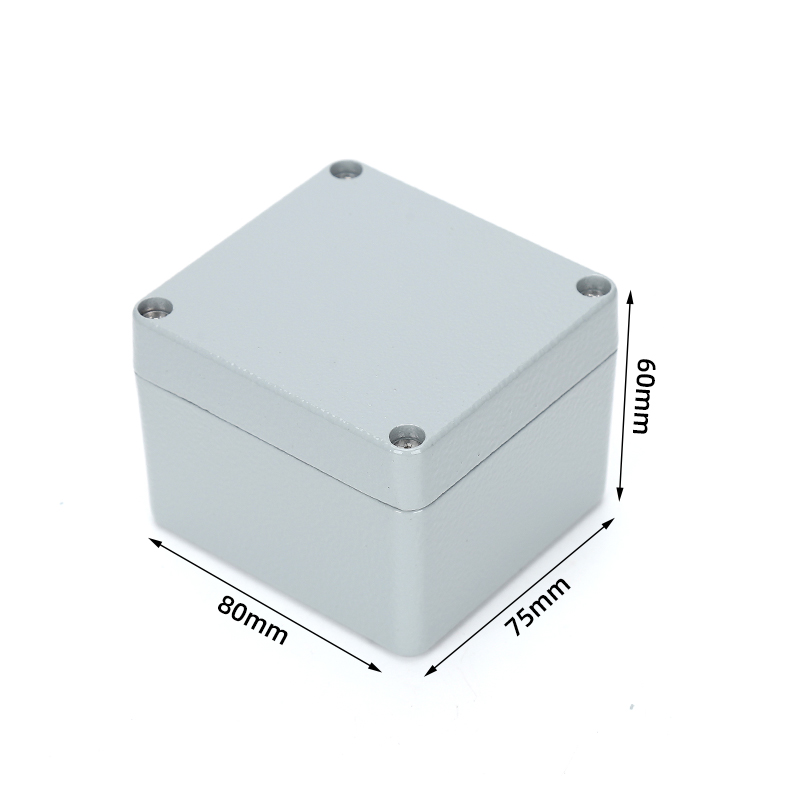

Aluminum electrical junction enclosure/box

Aluminum enclosures possess outstanding durability. The diecast aluminum enclosures we offer are made from high-quality aluminum alloy casting metal.

This kind of metal can keep its shape intact and stay firm when facing considerable force.

Moreover, aluminum is a metal with excellent electrical conductivity, which enables it to conduct electricity effectively. In most situations, aluminum doesn’t respond to magnetic force.

Thanks to these properties, aluminum serves as a superb shield against electromagnetic frequency (EMF) and radio frequency interference (RFI). Consequently, aluminum enclosures can be a valuable component in projects that require independent circuitry and minimal interference, helping to ensure the smooth operation of the overall system.

Aluminum alloys are naturally corrosion-resistant, so the enclosures are good for moisture-affected applications. We offer various finishes such as natural aluminum, powder coating, and black anodized finish. Diecasting leaves few seams or folds, just at the body-cover joint. Aluminum can protect against open-flame heat, but as it’s thermally conductive, it may not suit projects with temperature-sensitive electronics.

Benefits of aluminum enclosures:

- Durable: Maintains shape and rigidity under force.

- Conductive: Good for electrical conduction and shielding against interference.

- Corrosion-resistant: Suits moist or corrosive environments.

- Heat-resistant: Protects from high heat but may not work well with temperature-sensitive parts due to thermal conductivity.

- Aesthetic: Multiple finishes available.

- Seamless (diecasting): Few seams or folds, except at body-cover joint for a sleek look.

Plastic electrical junction enclosure/box

Plastic is an engineering material favored by most people and it offers several advantages. First of all, it is non-conductive, which is very necessary when worrying about electric shock, because non-conductivity can provide users with a certain degree of protection.

Cost is often a consideration as well, plastic is generally cheaper than metal, which is why plastic housings are so popular. Additionally, it is lighter than metal, which helps reduce shipping costs, especially when exporting to remote countries. Plastic is also resistant to corrosion and does not require additional coatings like steel or other metals.

Because plastic allows RFI and EMF waves to pass freely, it is ideal for electronic devices that need to send and receive electrical signals. We usually have two types of plastic boxes made of materials, one is ABS and the other is PC. Of course, there are also a mixture of ABS and PC. ABS cases are ideal for indoor projects and are relatively common, they come in a variety of sizes and provide a sturdy protective shell for a variety of electronics. Another material is PC. Polycarbonate shells are more suitable for outdoor use than ABS because they can withstand higher temperatures.

Benefits of Plastic enclosures:

- 1.Electrical Insulation: Non-conductive, protects from electrical issues and shocks.

- 2.Cost-Effectiveness: Usually cheaper than metal, helps cut costs.

- 3.Lightweight: Weighs less than metal, easy to handle and reduces transport costs.

- 4.Corrosion Resistance: Naturally resistant, no need for extra coatings.

- 5.Signal Transparency: Lets RFI and EMF waves pass through for signal transmission.

- 6.Versatility: ABS for indoor use with various sizes; polycarbonate for outdoor use against harsh weather.

In conclusion

All in all, HIGHYI’s aluminum and plastic enclosures each have their own advantages, depending on your electronic product design needs. If you are not sure about your usage requirements, you can consult us for more recommended information on the use of the box.