Standart Kutulara Karşı Su Geçirmez Buat Muhafazaları: Dayanıklılık Neden Önemlidir?

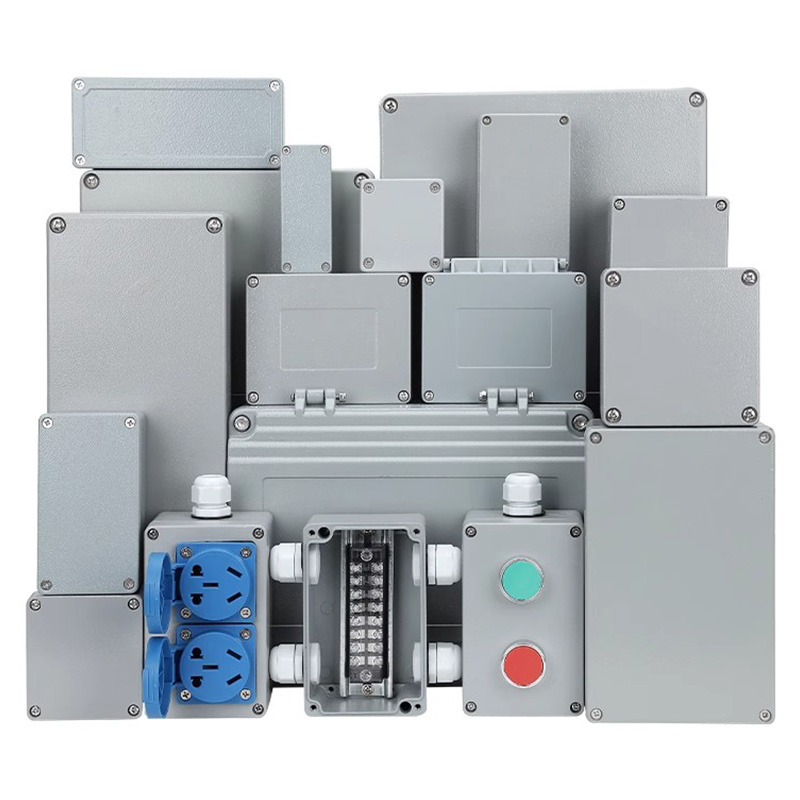

In today’s world of advancing technology and complex infrastructure, selecting the right enclosure for electrical and electronic components is crucial. Waterproof junction enclosures and standard boxes both serve to protect internal components, but their durability, environmental resistance, and applications set them apart. Here’s an in-depth comparison to help you understand why durability should be a top consideration when choosing an enclosure.

≡ The Role of Durability in Enclosures

Durability in an enclosure is not just about longevity; it directly impacts the safety, functionality, and maintenance requirements of the components inside. Waterproof junction enclosures, designed for challenging environments, offer enhanced protection against external factors such as:

- Moisture and water ingress

- Dust and debris

- UV radiation and extreme weather

- Impact and corrosion

Standard boxes, while suitable for controlled environments, often fall short in these areas.

≡ Key Differences Between Waterproof Junction Enclosures and Standard Boxes

| Özellik | Waterproof Junction Enclosures | Standard Boxes |

|---|---|---|

| Ingress Protection (IP) | Typically rated IP65, IP67, or higher; resistant to water, dust, and harsh weather. | Lower IP ratings, suitable for indoor use or less demanding environments. |

| Malzeme | High-quality ABS, polycarbonate, or stainless steel for added durability. | Often made of basic plastic or lightweight metals. |

| Applications | Outdoor, industrial, marine, or underground applications. | Indoor or sheltered settings with minimal exposure to environmental stress. |

| Maintenance | Minimal due to superior resistance to external damage. | Frequent maintenance or replacement may be required. |

≡ Why Waterproof Junction Enclosures Excel

- Long-Term Cost Efficiency

Although waterproof enclosures may have a higher upfront cost, their durability significantly reduces the need for frequent replacements, repairs, or maintenance. - Versatility Across Environments

Waterproof junction enclosures are ideal for diverse applications, including:- Outdoor electrical systems.

- Underground wiring projects.

- Marine and offshore installations.

- Renewable energy systems like solar and wind.

- Enhanced Safety

By preventing water ingress, short circuits, and contamination, these enclosures provide a safer environment for sensitive components, reducing the risk of system failures or accidents. - Customizable Options

Many waterproof enclosures come with features like gaskets, cable glands, and mounting brackets to enhance usability and meet specific project requirements.

≡ Limitations of Standard Boxes

- Limited Environmental Resistance

Standard boxes are not designed to withstand exposure to water, dust, or impact, making them unsuitable for outdoor or industrial use. - Higher Maintenance Costs

The lack of protective features often leads to quicker wear and tear, requiring more frequent interventions. - Restricted Application Scope

These boxes are typically confined to indoor use in controlled conditions, such as residential wiring or small-scale commercial applications.

≡ When to Choose Waterproof Junction Enclosures

Consider opting for waterproof enclosures if your application involves:

- Exposure to rain, splashes, or submerged conditions.

- Environments with high humidity or dust levels.

- Critical equipment that cannot afford downtime due to damage.

≡ Conclusion

Durability is not just a feature—it’s a necessity when it comes to protecting electrical and electronic components. While standard boxes may suffice for simple indoor applications, waterproof junction enclosures are the clear choice for any project requiring long-lasting, reliable, and environmentally resistant protection. By investing in durability upfront, you can ensure safety, reduce maintenance, and enhance the overall efficiency of your systems.