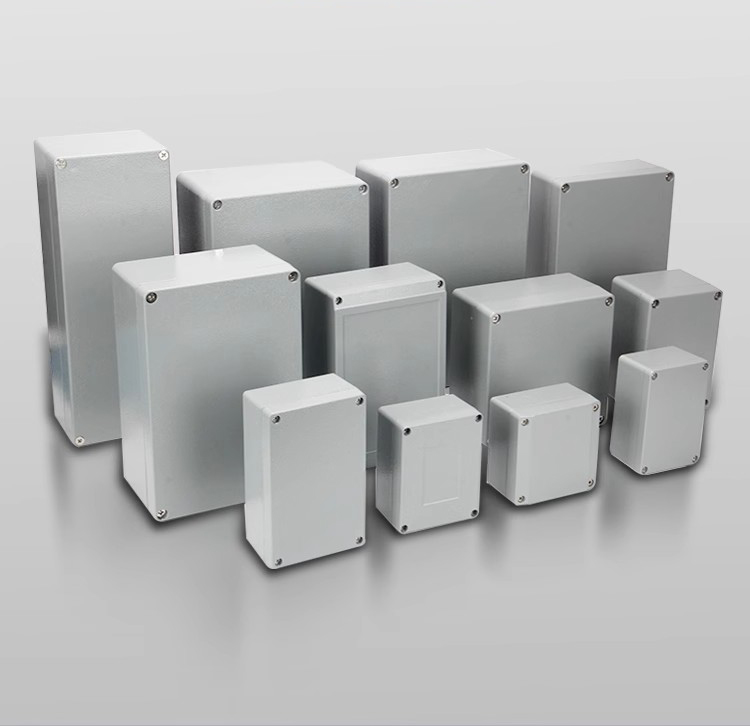

Aluminum enclosures serve as a wise option for transporting, safeguarding, and storing sensitive equipment. They are perfectly suited for applications that are exposed to extreme temperatures, corrosive surroundings, and high electromagnetic fields.

The durability and resistance properties of aluminum make it an excellent material for enclosing and protecting valuable and delicate equipment. Whether it’s for industrial use in harsh environments or for specialized applications that require protection from various external factors, aluminum enclosures offer a reliable solution.

They can withstand temperature fluctuations, resist corrosion from chemicals or moisture, and shield equipment from electromagnetic interference, ensuring the integrity and functionality of the sensitive equipment inside.

Advantages of aluminum electric enclose/box

1. Lighter weight

Aluminum boasts a high strength-to-weight ratio.

As a result, aluminum enclosures are remarkable for being lightweight while still possessing considerable strength. This unique combination makes them highly practical for a wide range of applications.

Their light weight makes them easy to handle and transport, reducing the effort and cost involved in moving them. At the same time, their strength ensures that they can provide reliable protection for the contents inside.

Whether used in electronics, industrial equipment, or other fields, aluminum enclosures offer the advantage of durability without the excessive weight that might be a drawback with other materials.

This quality allows for more efficient use of space and resources, as well as easier installation and maneuverability.

2.Extremely Strong

The strength of aluminum endows it with significantly better fracture toughness compared to most other materials employed in enclosure construction. It displays remarkable resistance to impacts, mechanical breakage, and the propagation of fractures. Aluminum enclosures do not readily succumb to stress, tear, or crack

3. Extraordinary Resistance to Corrosion

The characteristics of aluminum remain consistent over a broad temperature range from -80 °C to +150 °C. In cold weather conditions, aluminum enclosures do not turn more fragile and brittle. On the contrary, the tensile strength increases without any loss of ductility. The low coefficient of thermal expansion of aluminum enables it to endure higher temperatures without undergoing distortion. This remarkable temperature stability makes aluminum enclosures highly reliable in various environments. Whether in freezing cold climates or in areas with high heat, they can maintain their structural integrity and functionality. The ability to handle extreme temperatures without significant changes in properties ensures that the enclosures can protect the contents inside effectively. It also reduces the risk of damage due to thermal stress, providing a durable and long-lasting solution for different applications.

4. Insensitive to Temperature Extremes

Light is another major contributor to mold growth, so storing your grain in a dark place or a light-proof container – like a plastic bucket – is necessary if you want it to last a long time.

While it may be tempting to store your grains in the basement or shed as a low-light place, make sure you’re considering all the other factors of spoilage like temperature and moisture. You need to monitor all three to keep your grains usable as long as possible.

5. Naturally Protects Electronics

Aluminum holds the highest electrical conductivity-to-weight ratio among all metals. An aluminum enclosure is superb for RFI (Radio Frequency Interference)/EMI (Electromagnetic Interference) shielding and for controlling ESD (electrostatic discharge). Additionally, aluminum is an efficient reflector for externally generated interference, specifically electromagnetic wavelengths of radio and radar. This unique property makes it an ideal choice for applications where protection from electromagnetic interference is crucial. Whether it’s in electronics manufacturing, telecommunications, or other industries that deal with sensitive electrical equipment, aluminum enclosures can provide effective shielding. The high electrical conductivity of aluminum helps in dissipating static charges and blocking unwanted electromagnetic signals. It ensures that the enclosed equipment operates smoothly without being affected by external interference. Moreover, its ability to reflect radio and radar wavelengths can be advantageous in applications where signal isolation or protection from external electromagnetic waves is required.

6. Excellent Heat Dissipation

Aluminum is extensively utilized in heat sinks and heat exchangers due to its elevated thermal conductivity. In a shipping case, it proficiently conducts heat away from electronics and other equipment. Aluminum also has a high reflectance to encroaching radiated heat, such as sunlight. In fact, aluminum has a light reflectivity of over 80%. This combination of properties makes aluminum an excellent choice for applications where heat management is critical. It can quickly transfer heat generated by electrical components, preventing overheating and ensuring the proper functioning of the equipment. At the same time, its high reflectance to sunlight and other sources of radiated heat helps in reducing the heat load on the enclosure. This not only protects the contents inside from excessive heat but also reduces the need for additional cooling measures. Whether in outdoor applications or in environments with high heat sources, aluminum’s thermal properties make it a reliable and efficient material for protecting and cooling sensitive equipment.

7. Suited for Harsh Environments

In rugged and outdoor environments, aluminum enclosures can be equipped with various options to fulfill watertight, splash-proof, drip-proof, and salt spray requirements. Water vapor will not permeate through aluminum or through a welded seam. This makes aluminum enclosures highly suitable for use in harsh outdoor conditions where exposure to moisture and salt spray is common. The ability to meet these stringent requirements ensures that the enclosures can protect the contents inside from water damage and corrosion. Whether it’s for industrial equipment in coastal areas or for outdoor electronics installations, aluminum enclosures with these features provide reliable protection. The impermeability of aluminum to water vapor and the integrity of welded seams offer peace of mind, knowing that the enclosed equipment will remain safe and functional even in the face of challenging environmental conditions.

8. Low Cost Customization

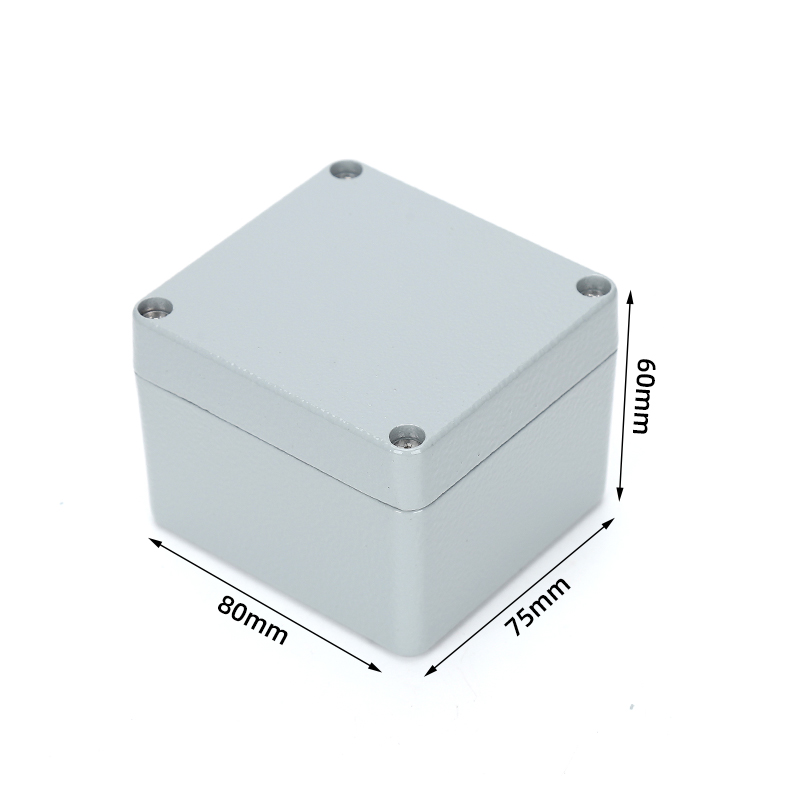

Aluminum enclosures can be effortlessly customized through secondary operations like drilling, laser cutting, riveting, welding, brazing, soldering, and more. There is no necessity to pay for a special mold. Aluminum is frequently easier to modify than enclosures made of other materials. This flexibility in customization allows for tailoring the enclosures to specific requirements. Whether it’s adding holes for cable pass-throughs, cutting custom shapes for specific components, or performing other modifications, aluminum enclosures offer a practical solution. The ease of modification means that changes can be made quickly and cost-effectively, without the need for expensive tooling or molds. This makes aluminum enclosures a popular choice for applications where unique configurations or modifications are required. Whether for a one-off project or for mass customization, aluminum’s adaptability makes it a versatile material for enclosure design.

9. Beautiful Finishes

Aluminum enclosures can accommodate a wide variety of finishes, including mechanical ones like brushing or polishing and chemical finishes like anodizing. Additionally, almost any coating, like paint and powder coatings, can be applied to aluminum enclosures.

10. Aluminum is Safe

Aluminum is non-toxic, odorless, tasteless, non-absorbing, non-sparking, non-magnetic, and non-flammable. As a result, aluminum enclosures can be utilized in a diverse range of special environments, including sanitary and clean rooms, food service areas, and many volatile applications. Moreover, aluminum is fully recyclable. This combination of properties makes aluminum enclosures an excellent choice for applications where safety and environmental sustainability are crucial. The non-toxic and non-flammable nature ensures that they pose no risk in sensitive environments. The recyclability of aluminum also contributes to its appeal, as it reduces waste and environmental impact. Whether in healthcare facilities, food processing plants, or other specialized settings, aluminum enclosures offer a reliable and eco-friendly solution.