ジャンクションボックス設計の革新:スマートな機能とカスタマイズオプション

The design of junction boxes has evolved significantly over the years, especially with the rise of advanced technology and changing industry requirements. While traditional junction boxes were designed primarily for basic electrical protection, modern junction boxes now include smart features, enhanced materials, and a range of customization options that allow them to meet the demands of increasingly complex systems.

Here’s a deep dive into some of the latest innovations in junction box design, including smart features and customization options.

≡ Smart Features in Junction Boxes

≡ 1. Integrated Temperature Sensors

Modern junction boxes are increasingly equipped with temperature sensors that monitor the internal temperature of the box. This is especially useful in environments where electrical components are at risk of overheating due to high power usage or poor ventilation. These sensors can trigger alarms or send data to a central system to prevent damage before it happens.

- Use Case: In industrial applications where high currents are being carried through the junction box, real-time temperature monitoring can help identify overheating components, improving safety and reducing the risk of fires or system failures.

≡ 2. Humidity and Moisture Detection

Some junction boxes are now designed with humidity or moisture sensors that detect the presence of water or humidity inside the box. This is particularly important in outdoor or industrial settings where water ingress can lead to corrosion, electrical faults, or even dangerous short circuits.

- Use Case: In coastal or marine environments, where humidity and saltwater can damage electrical components, a moisture-detecting junction box provides an early warning, allowing maintenance crews to take preventive actions.

≡ 3. Wireless Monitoring and Alerts

With the advent of IoT (Internet of Things), junction boxes can now be equipped with wireless monitoring systems that track and report data remotely. These systems can send real-time data to a smartphone, tablet, or computer, providing immediate alerts for conditions like temperature spikes, moisture, or other anomalies that could affect the performance of the electrical system.

- Use Case: In critical infrastructure such as data centers or power plants, wireless monitoring allows technicians to receive instant notifications of any issues, improving response times and reducing downtime.

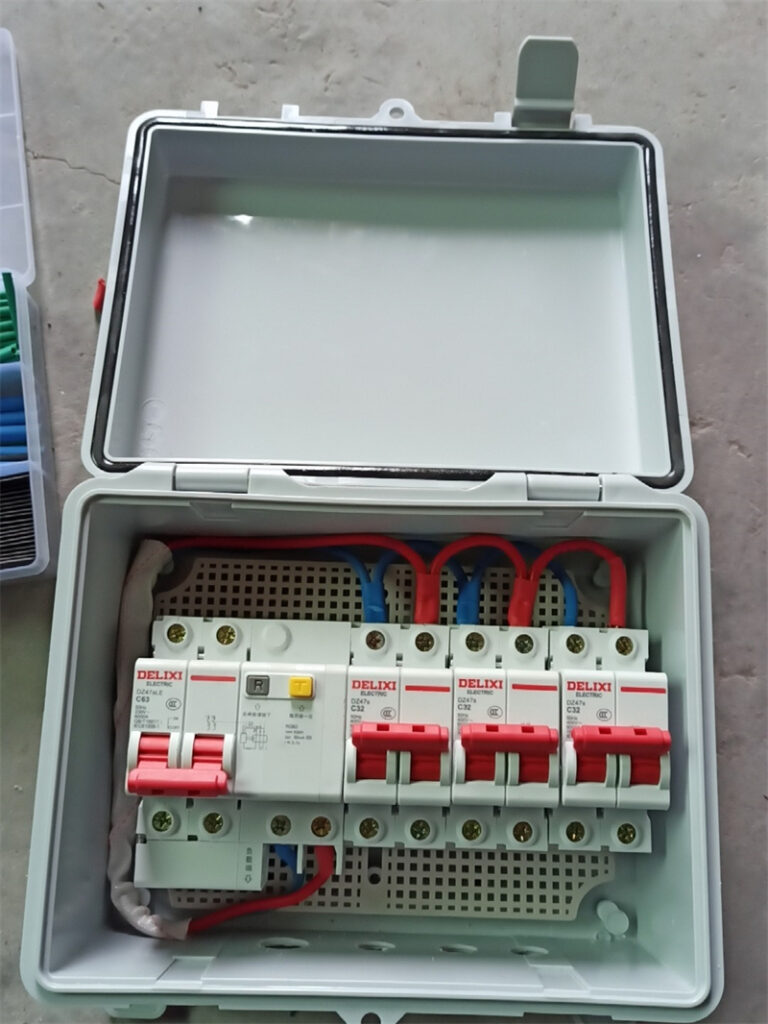

≡ 4. Built-In Circuit Protection

Innovative junction boxes now come with built-in circuit protection, such as fuses or circuit breakers, which can automatically shut down the system in case of electrical overloads or short circuits. This feature helps to prevent costly damage to both the junction box and the connected electrical components.

- Use Case: In systems with high-powered equipment or in hazardous environments, this built-in protection can significantly reduce the risk of system failures and increase safety for workers.

≡ Customization Options for Junction Boxes

Customization of junction boxes is an increasingly important trend as more specialized applications and industries demand bespoke solutions. Some of the key customization options available include:

≡ 1. Size and Shape Variability

Junction boxes can be custom-designed to fit specific space requirements, whether they are compact and sleek for residential use or large and robust for industrial applications. Custom sizes allow junction boxes to fit into existing infrastructure, minimizing the need for alterations or modifications.

- Use Case: For projects where space is limited, such as in tight machinery enclosures or confined areas, custom-sized junction boxes can be made to fit precisely, ensuring efficient use of space.

≡ 2. Material Selection

Different materials offer varying levels of protection depending on the application. Custom junction boxes can be made from materials such as:

- Plastic: Lightweight, cost-effective, and corrosion-resistant, ideal for indoor or less harsh environments.

- ステンレス鋼: Offers high strength and corrosion resistance, perfect for outdoor, industrial, or corrosive environments.

- アルミニウム: A lightweight, durable option that’s suitable for many general-purpose applications.

- Die-Cast Metal: Often used for high-impact or weatherproof applications, providing an extra layer of durability and protection.

- Use Case: A custom aluminum junction box may be chosen for its lightweight and high strength properties in a mobile equipment application, while a stainless steel box might be selected for its corrosion resistance in a chemical plant.

≡ 3. Cable Entry and Exit Configurations

Junction boxes can be customized with various cable entry and exit configurations, including cable glands, knockout holes, or flexible conduits. These configurations ensure that the junction box can accommodate the number and type of cables required for the application.

- Use Case: For a project that involves multiple cables or specialized connectors, a junction box with a customized configuration of cable glands can simplify the installation process and improve overall functionality.

≡ 4. Color and Branding Customization

While junction boxes are often a neutral color (such as gray or black), custom colors and branding can be incorporated for aesthetic reasons or for easy identification. This is especially helpful in environments where multiple systems or projects are running simultaneously.

- Use Case: For a company that wants to promote its brand or maintain a visually uniform system across multiple installations, custom colors and logos can be added to the junction boxes.

≡ 5. Enhanced Sealing Options

Custom sealing options can be applied to junction boxes to improve their resistance to dust, water, and other environmental contaminants. The use of high-quality gaskets and sealing materials can provide superior protection, especially for boxes used in extreme environments.

- Use Case: For applications in areas that are prone to flooding or heavy rain, junction boxes can be custom-sealed to ensure a watertight environment that protects internal components.

≡ 6. Modular Designs

Modular junction boxes allow for greater flexibility by enabling components such as internal dividers, racks, and mounting plates to be adjusted, added, or removed. This makes it easier to expand or modify the junction box as the system requirements evolve over time.

- Use Case: In a growing industrial facility, a modular junction box can be expanded or reconfigured as new equipment is added, providing cost-effective scalability without needing to replace the entire box.

≡ Benefits of Smart Features and Customization

- Increased Efficiency: With real-time monitoring and automatic protection features, junction boxes help prevent system failures and reduce maintenance time.

- Enhanced Safety: Features like temperature sensors, circuit protection, and moisture detection increase safety, protecting both workers and electrical components from damage.

- Cost-Effectiveness: Customization allows businesses to get exactly what they need without paying for unnecessary features, while smart features help extend the life of equipment and reduce downtime.

- Better Performance: Tailored solutions that fit the specific needs of the environment can improve the overall performance of electrical systems.

≡ 結論

Innovations in junction box design, such as smart features and customizable options, have made these essential components even more versatile and capable. From integrated sensors to enhanced materials and modular designs, the latest junction boxes offer not only superior protection but also greater flexibility, efficiency, and safety. Whether you’re looking for a basic solution or a highly specialized junction box, the ability to customize the design and incorporate smart technologies ensures that these boxes meet the needs of modern electrical systems in a variety of industries.

As the demand for smarter, safer, and more adaptable electrical solutions continues to grow, We Highyi Electric junction box manufacturers are poised to offer even more innovative options that push the boundaries of what these boxes can do.