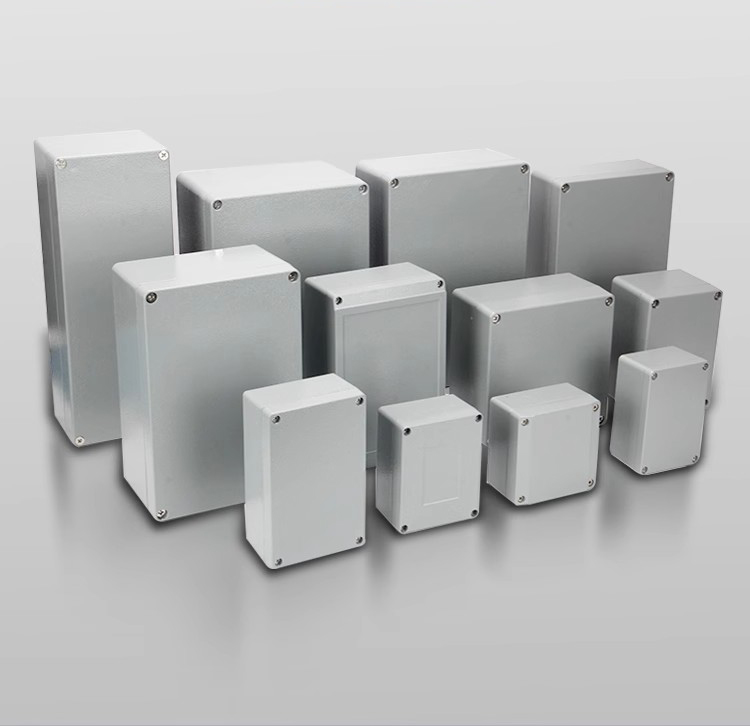

アルミ鋳造防水ボックスは、精密機器の輸送、保護、保管に最適です。極端な温度、腐食性の強い環境、高い電磁場にさらされるなど、屋外の過酷な条件に最適です。

この記事では、アルミ鋳物防水のいくつかの利点を探ります。

アルミニウム製電気接続箱の利点

1.軽量

アルミニウムは強度重量比が高い。

そのため、アルミニウム製エンクロージャーは軽量でありながら、かなりの強度を備えている。この特性により、広く使用され、非常に実用的です。

アルミの箱は比較的軽いため、取り扱いや輸送が容易で、(他の金属に比べて)取り扱いに必要な作業量やコストを削減することができます。同時に

その強度は他の金属と比べても遜色なく、内部の部品をしっかりと支えることができる。

同時に、軽量であるということは、同じ体積に対して使用される材料の重量が少ないということであり、相対的に価格が安くなる。

2.非常に強い

アルミニウムの強度は、住宅建設に使用される他のほとんどの材料よりも破壊靭性が著しく優れています。衝撃、機械的破壊、破壊伝播に対して優れた耐性を示します。アルミニウム製ハウジングは、応力、引き裂き、亀裂などの外力によって容易に損傷することはありません。

3.並外れた耐腐食性

アルミニウムの特性は、-80 °Cから+150 °Cまでの広い温度範囲で一貫しています。寒冷な気象条件下でも、アルミニウム製エンクロージャーが壊れやすく脆くなることはありません。それどころか、延性を失うことなく引張強度が増加します。アルミニウムの熱膨張係数が低いため、変形することなく高温に耐えることができます。この優れた温度安定性により、アルミニウム製エンクロージャーはさまざまな環境で高い信頼性を発揮します。凍てつくような寒冷地でも、高熱の地域でも、構造的完全性と機能性を維持することができます。特性を大きく変えることなく極端な温度に対応できるため、エンクロージャーは内部の内容物を効果的に保護することができます。また、熱応力による損傷のリスクを低減し、さまざまな用途に耐久性と長寿命のソリューションを提供します。

4.極端な温度に弱い

光もカビ発生の主な原因なので、穀物を長持ちさせたいなら、暗い場所か、プラスチックのバケツのような光を通さない容器に保管することが必要だ。

日当たりの悪い地下室や物置に穀物を保管したくなるかもしれませんが、温度や湿気など、腐敗の他の要因もすべて考慮してください。穀物をできるだけ長く使えるようにするには、この3つを監視する必要があります。

5.電子機器を自然に保護

アルミニウムは、あらゆる金属の中で最も高い導電率対重量比を誇ります。アルミニウム製エンクロージャーは、RFI(無線周波数干渉)/EMI(電磁干渉)シールドやESD(静電気放電)制御に最適です。さらに、アルミニウムは外部から発生する干渉、特にラジオやレーダーの電磁波を効率的に反射します。このユニークな特性により、アルミニウムは電磁干渉からの保護が重要な用途に理想的な選択肢となります。電子機器製造業、電気通信業など、繊細な電気機器を扱う産業であれ、アルミニウム製エンクロージャは効果的なシールドを提供できます。アルミニウムの高い導電性は、静電気の放散と不要な電磁信号の遮断に役立ちます。外部干渉の影響を受けることなく、密閉された機器がスムーズに動作することを保証します。さらに、ラジオやレーダーの波長を反射する能力は、信号の分離や外部電磁波からの保護が必要な用途に有利です。

6.優れた放熱性

アルミニウムは熱伝導率が高いため、ヒートシンクや熱交換器に広く利用されています。輸送ケースの場合、電子機器やその他の機器から熱を効率よく逃がします。アルミニウムはまた、太陽光のような輻射熱に対する反射率も高い。実際、アルミニウムの光反射率は80%以上です。このような特性を併せ持つアルミニウムは、熱管理が重要な用途に最適です。アルミニウムは、電気部品から発生する熱を素早く伝達し、過熱を防ぎ、機器の適切な機能を保証します。同時に、太陽光やその他の放射熱源に対する反射率が高いため、エンクロージャーの熱負荷を軽減することができます。これにより、内部の内容物を過度の熱から保護するだけでなく、追加の冷却手段の必要性も低減します。屋外用途であれ、高熱源のある環境であれ、アルミニウムの熱特性は、繊細な機器を保護し冷却するための信頼できる効率的な材料となります。

7.過酷な環境に適している

過酷な屋外環境では、アルミニウム製エンクロージャにさまざまなオプションを装備することで、防水、防滴、塩水噴霧の要件を満たすことができます。水蒸気はアルミニウムや溶接継ぎ目から浸透することはありません。このため、アルミ製エンクロージャは、湿気や塩水噴霧にさらされることが多い過酷な屋外環境での使用に非常に適しています。このような厳しい要件を満たすことができるため、エンクロージャーは内部の内容物を水による損傷や腐食から確実に保護することができます。沿岸地域の産業用機器であれ、屋外の電子機器設置であれ、これらの特徴を備えたアルミニウム製エンクロージャーは、信頼性の高い保護を提供します。水蒸気に対するアルミニウムの不浸透性と溶接継ぎ目の完全性は、厳しい環境条件に直面しても、密閉された機器が安全で機能的であることを保証し、安心を提供します。

8.低コストでのカスタマイズ

アルミ製エンクロージャーは、穴あけ、レーザー切断、リベット留め、溶接、ろう付け、はんだ付けなどの二次加工によって、簡単にカスタマイズすることができます。特別な金型を購入する必要はありません。アルミニウムは、他の材料で作られた筐体よりも加工が容易な場合が多い。このカスタマイズの柔軟性により、特定の要件に合わせてエンクロージャーを調整することができます。ケーブル・パススルー用の穴を追加したり、特定のコンポーネント用にカスタム形状をカットしたり、その他の変更を行う場合でも、アルミニウム製エンクロージャーは実用的なソリューションを提供します。変更が容易であるため、高価な金型や工具を使用することなく、迅速かつコスト効率よく変更できます。このため、アルミニウム製エンクロージャは、独自の構成や修正が必要な用途によく選ばれています。単発のプロジェクトであれ、マスカスタマイゼーションであれ、アルミニウムの適応性により、エンクロージャ設計のための汎用性の高い材料となります。

9.美しい仕上げ

アルミニウム製エンクロージャーは、ブラッシングや研磨のような機械的仕上げや陽極酸化のような化学的仕上げなど、さまざまな仕上げに対応できます。さらに、塗装や粉体塗装など、ほとんどすべてのコーティングをアルミニウム製エンクロージャーに施すことができます。

10.アルミニウムは安全

アルミニウムは無毒、無臭、無味、非吸収性、非スパーク性、非磁性、非可燃性です。その結果、アルミニウム製エンクロージャは、サニタリーやクリーンルーム、食品サービスエリア、多くの揮発性用途など、多様な特殊環境で利用できます。さらに、アルミニウムは完全にリサイクル可能です。このような特性を併せ持つアルミニウム製エンクロージャは、安全性と環境の持続可能性が重要な用途に最適です。無毒性で不燃性であるため、デリケートな環境でもリスクがありません。アルミニウムのリサイクル可能性も、廃棄物や環境への影響を減らすという点で魅力的です。医療施設、食品加工工場、その他の特殊な環境にかかわらず、アルミニウム製エンクロージャは信頼性が高く、環境に優しいソリューションを提供します。