Der Kauf des richtigen Schaltschranks ist die erste Überlegung, um das ordnungsgemäße Funktionieren elektrischer Geräte zu gewährleisten, vor allem im Hinblick auf Größe, Material, innere Konstruktion und Schutzart.

Heute werden wir das IP-Bewertungssystem erörtern, ein weltweit gebräuchliches System zur Bewertung der Schutzqualität von elektrischen Gehäusen. Genauer gesagt werden wir erörtern, was die Schutzart IP67 bedeutet und wann sie am ehesten zum Einsatz kommt. Abschließend werden wir einige der vielen qualitativ hochwertigen Gehäuse von HIGHYI vorstellen, um Ihnen die Auswahl des am besten geeigneten Gehäuses zum Schutz Ihrer wichtigen Geräte zu erleichtern.

Was bedeutet IP67?

Die IP-Einstufung oder Ingress Protection (IP) ist ein Standard, der von der Internationale Elektrotechnische Kommission (IEC) zur Beschreibung des Schutzgrades, den das Gehäuse eines elektrischen Geräts gegen das Eindringen von Fremdkörpern bietet. Die IP-Klassifizierung besteht aus zwei Zahlen, wobei die erste Zahl den Grad des Staubschutzes und die zweite Zahl den Grad der Wasserdichtigkeit angibt.http://www.iec.ch/index.htm

Die erste Ziffer (6) von IP67 steht für den höchsten Schutzgrad gegen das Eindringen von Festkörpern, wie Staub, Schmutz oder Fingerkontakt. Die zweite Ziffer (7) steht für einen hohen Schutzgrad gegen Flüssigkeiten, wie Regen, Tau oder Schmutzwasser, das von Fahrzeugen aufgespritzt wird. Im Allgemeinen müssen Gehäuse der Schutzart IP67 dem Eindringen von Staub widerstehen und können für mindestens 30 Minuten in eine Tiefe von 150 mm bis 1000 mm (1 Meter) eingetaucht werden. IP67-Gehäuse funktionieren garantiert in Innenräumen, im Freien, in feuchten und rauen industriellen und kommerziellen Umgebungen einwandfrei.

Sehen Sie, wie HIGHYI-Gehäuse mit IP 67 abschneiden:

Wie Sie Ihre gewünschte IP-Einstufung wählen?

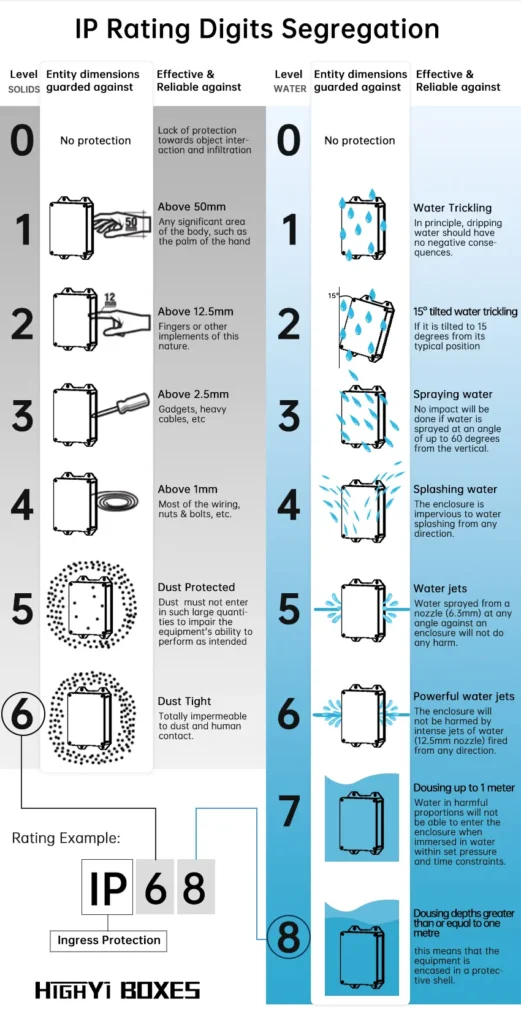

Nachdem Sie die Bedeutung von IP verstanden haben, können Sie bestimmen, welchen Schutzgrad Ihr Gerät benötigt, um den Auswirkungen der Umwelt zu widerstehen.

Wir empfehlen Ihnen, die Tabelle heranzuziehen und den Schutzgrad von festen und flüssigen Stoffen zu beschreiben, um den Wasserschutzgrad zu bestimmen.

Natürlich können Sie auch direkt eine hohe IP-Stufe verwenden, die die Anforderungen einer niedrigeren Schutzstufe abdecken kann,

wie z.B. unsere HIGHYI IP67 wasserdichte Aluminium-Gussbox / wasserdichte Kunststoffbox zu testen.

Wo werden IP67-Gehäuse eingesetzt?

IP67-Gehäuse werden in vielen Bereichen eingesetzt:

- Industriell : In Fertigungsbetrieben zum Schutz von Bauteilen vor Staub und in Outdoor-Elektrogeräten vor Staub und Wasser.

- TransportUnter der Motorhaube von Fahrzeugen und für Schiffsausrüstungen, um Wasser- und Staubeinwirkung standzuhalten.

- Outdoor & Infrastruktur : Für Verkehrsleitsysteme und Telekommunikations-Basisstationen im Freien.

- Essen & Trinken In Verarbeitungsbetrieben bei der Reinigung und in feuchter Umgebung.

- Landwirtschaft Für Steuergeräte von Bewässerungssystemen, die auf den Feldern Staub und Wasser ausgesetzt sind.

Wo liegen die Unterschiede zwischen IP-Bewertung und NEMA-Gehäusen?

NEMA-Gehäuse

Prüfung: Die NEMA hat ihre eigenen Prüfmethoden, die für ihre Normen spezifisch sind. Bei diesen Tests werden verschiedene Faktoren berücksichtigt, die für den nordamerikanischen Markt und industrielle Einsatzszenarien relevant sind. Die NEMA-Bewertungen werden vor allem in den Vereinigten Staaten und Kanada häufiger verwendet und spezifiziert.

Schutzniveau: NEMA-Gehäuse (National Electrical Manufacturers Association) verfügen über eine eigene Reihe von Schutzklassen. Sie haben zwar einige Ähnlichkeiten mit den IP-Einstufungen in Bezug auf den Schutz vor Staub und Wasser, bieten aber auch zusätzliche Aspekte. So können NEMA-Gehäuse auch Schutz vor Korrosion und atmosphärischen Gasen bieten, was von den grundlegenden IP-Schutzklassen nicht abgedeckt wird. NEMA-Gehäuse sind für den Einsatz in nordamerikanischen Industrieanwendungen konzipiert und auf die besonderen Umweltbedingungen in dieser Region zugeschnitten, z. B. den Umgang mit aggressiveren Industriechemikalien oder bestimmte Klimabedingungen.

| NEMA | IP |

| 1 | 10 |

| 2 | 11 |

| 3 | 54 |

| 3r | 14 |

| 3s | 54 |

| 4 und 4x | 55 |

| 5 | 52 |

| 6 und 6p | 67 |

| 12 und 12k | 52 |

| 13 | 54 |

| 4 | IP65 / IP66 |

| 4X | IP65 ⁄ IP66 |

Wesentliche Unterschiede

- Umfang des Schutzes: IP67 konzentriert sich hauptsächlich auf den Schutz vor Staub und Wasser. Im Gegensatz dazu bieten NEMA-Gehäuse je nach NEMA-Einstufung einen umfassenderen Schutz, der sich auch auf Aspekte wie Korrosions- und Gasschutz erstrecken kann.

- Geografische Prävalenz: IP67 ist ein internationaler Standard und wird weltweit verwendet. NEMA-Gehäuse und ihre Nennwerte sind eher in Nordamerika verbreitet, obwohl sie auch in anderen Regionen zu finden sind, wenn eine Kompatibilität mit nordamerikanischen Industrieanlagen besteht oder spezifische Anforderungen an die zusätzlichen Schutzmerkmale von NEMA gestellt werden.

- Größe und Kosten: NEMA-Gehäuse sind in der Regel größer als Gehäuse, die nur die IP67-Norm erfüllen. Aufgrund ihrer umfassenderen Schutzfunktionen und der Tatsache, dass sie in der Regel für rauere Industrieumgebungen gebaut werden, sind sie auch oft teurer. Dies kann dazu führen, dass sie sich weniger für Anwendungen eignen, bei denen der Platz begrenzt ist oder die Kosten einen wichtigen Faktor darstellen, während IP67-Gehäuse eine kompaktere und kostengünstigere Wahl sein können, wenn nur ein grundlegender Staub- und Wasserschutz erforderlich ist.

- Eignung der Anwendung: Für Anwendungen, bei denen es in erster Linie um einfachen Staub- und Wasserschutz in relativ normalen Umgebungsbedingungen geht (wie bei vielen Unterhaltungselektronikgeräten oder einigen Außeninstallationen in milderen Klimazonen), können Gehäuse der Schutzart IP67 ausreichend sein. In industriellen Umgebungen in Nordamerika, die extremeren chemischen Einflüssen ausgesetzt sind, in denen raue Witterungsbedingungen in Kombination mit industriellen Schadstoffen herrschen oder in denen der Schutz vor Korrosion von entscheidender Bedeutung ist, sind NEMA-Gehäuse mit entsprechenden Schutzklassen jedoch besser geeignet.