≡ Abzweigkästen als stille Wächter: Wie sie die Sicherheit in extremen Umgebungen erhöhen

Junction boxes are often taken for granted in most electrical systems, yet they play a crucial role in ensuring safety, reliability, and efficiency. While most discussions about junction boxes revolve around their basic functions—protecting electrical connections and preventing water or dust ingress—there’s an area that’s rarely explored: their role in extreme environments. These environments, whether they are high-temperature industrial settings, underwater applications, or hazardous locations, require junction boxes that go beyond the ordinary. This blog explores how junction boxes are designed and utilized in such challenging environments and why they are often the unsung heroes in industrial safety.

≡ 1. Junction Boxes in High-Temperature and High-Humidity Environments

High-temperature and high-humidity environments are found in industries such as petrochemicals, mining, and energy production, where electrical systems are vulnerable to extreme heat and moisture. In these settings, junction boxes don’t just serve as protective enclosures—they act as thermal and moisture barriers.

- Heat Resistance: Junction boxes in high-temperature environments are often made of specialized materials like aluminum, stainless steel, or thermoplastic composites that can withstand continuous exposure to heat. Some junction boxes also incorporate heat shields oder insulating layers to prevent the internal components from being damaged.

- Humidity Resistance: In humid or corrosive environments, junction boxes are designed with high IP ratings (IP66 or IP67) and can incorporate corrosion-resistant coatings to ensure long-term durability and safety. The sealing mechanisms, such as silicone gaskets, are critical to prevent moisture from entering and causing short circuits or rust.

≡ 2. Junction Boxes in Explosive Atmospheres: Beyond the Norm

When it comes to hazardous locations where explosive gases or dust can be present (such as oil rigs, chemical plants, or grain silos), junction boxes are built to prevent sparks or electrical arcs that could lead to fires or explosions. These environments require Ex-rated junction boxes, which are specifically designed for such explosive atmospheres.

- Explosion-proof Design: Ex-rated junction boxes must meet specific international standards like ATEX (European Union) or IECEx (International) certifications. These boxes are typically constructed from heavy-duty metals, like cast aluminum, and feature intrinsic safety features that prevent ignition of explosive gases.

- Flameproof Construction: Some junction boxes are equipped with flameproof enclosures that contain any sparks or hot gases within the box, preventing ignition of flammable substances in the external environment.

≡ 3. Subsea Junction Boxes: Ensuring Functionality Underwater

Junction boxes play an essential role in underwater or subsea applications, where traditional electrical enclosures would fail due to the harsh conditions. In offshore energy systems, underwater sensors, and marine operations, junction boxes are built to withstand extreme water pressure, salt corrosion, and biofouling.

- Waterproof and Pressure-Proof: Subsea junction boxes must endure high pressure and maintain watertight integrity at depths of thousands of meters. They are often constructed from high-strength metals like titanium oder specialized polymers that offer high resistance to corrosion and pressure.

- Long-Term Sealing: To prevent seawater ingress, these boxes utilize advanced sealing methods, including O-rings und vacuum-sealed compartments, ensuring that internal components remain dry even in the harshest marine environments.

- Resilience to Biofouling: Subsea junction boxes are often treated with anti-fouling coatings to prevent the growth of marine organisms, which could clog or damage the enclosures over time.

≡ 4. Junction Boxes in Space Exploration: A New Frontier

Junction boxes are also crucial in space exploration, where extreme conditions such as zero gravity, vacuum, high radiation, and temperature fluctuations test the limits of materials and components. In spacecraft, satellites, and space stations, junction boxes help to maintain electrical safety and ensure uninterrupted performance.

- Space-Grade Materials: For space applications, junction boxes are typically made from materials like titanium alloys und high-performance plastics that can withstand both extreme cold and intense heat. They must be resistant to radiation, which can cause long-term degradation of electronic components.

- Low Outgassing Properties: In the vacuum of space, materials can release trapped gases in a phenomenon known as outgassing, which could contaminate sensitive equipment. Space-grade junction boxes are designed with low outgassing materials to prevent this issue.

- Radiation Protection: Some junction boxes are shielded with radiation-resistant materials to protect the internal components from harmful cosmic rays and solar radiation, ensuring the longevity of the electrical systems in space missions.

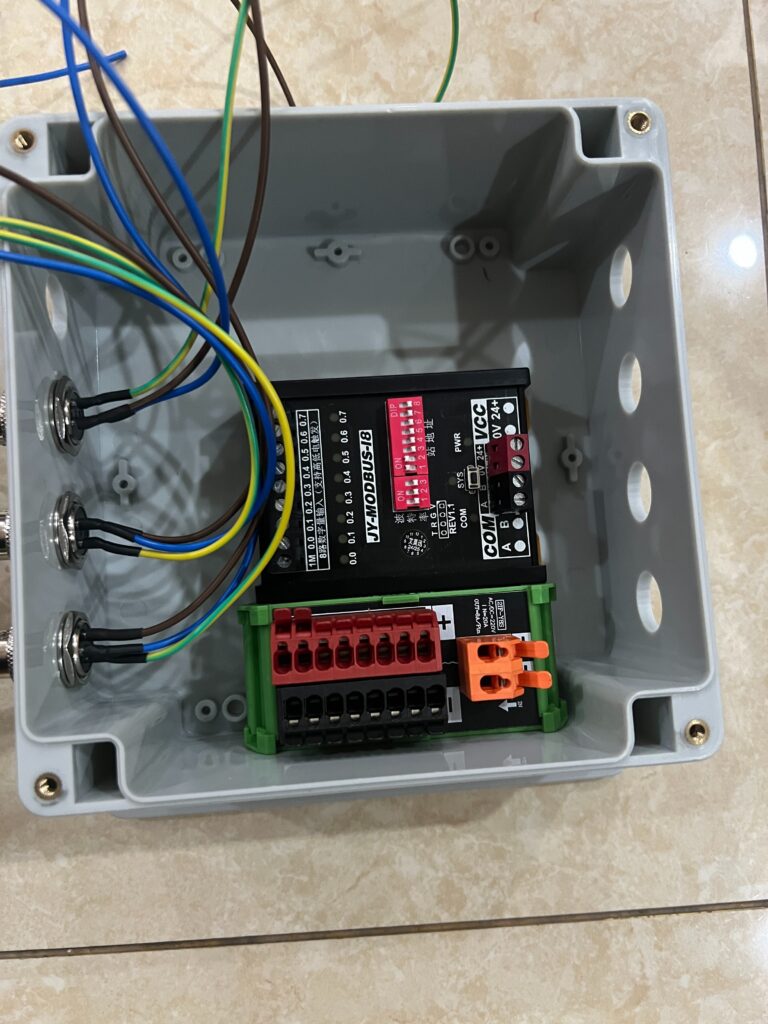

≡ 5. The Role of Junction Boxes in Industrial Automation and Smart Manufacturing

In industrial automation and smart manufacturing, junction boxes are increasingly being used in Industry 4.0 environments to support connectivity, remote monitoring, and predictive maintenance. They are integral to sensor networks, robotic systems, and smart factories.

- Integration with IoT: Junction boxes are evolving to include smart features like sensors, connectors, and communication ports. These boxes are part of the Industrial Internet of Things (IIoT), enabling data collection, remote monitoring, and predictive analysis.

- Real-time Monitoring: In automated factories, junction boxes are designed with real-time monitoring systems that track the health of electrical components, alerting operators to potential failures before they occur.

- Customizable Features: Modern junction boxes can be tailored to fit specific automation needs, with options for temperature sensors, humidity sensors, and environmental monitoring built directly into the enclosure.

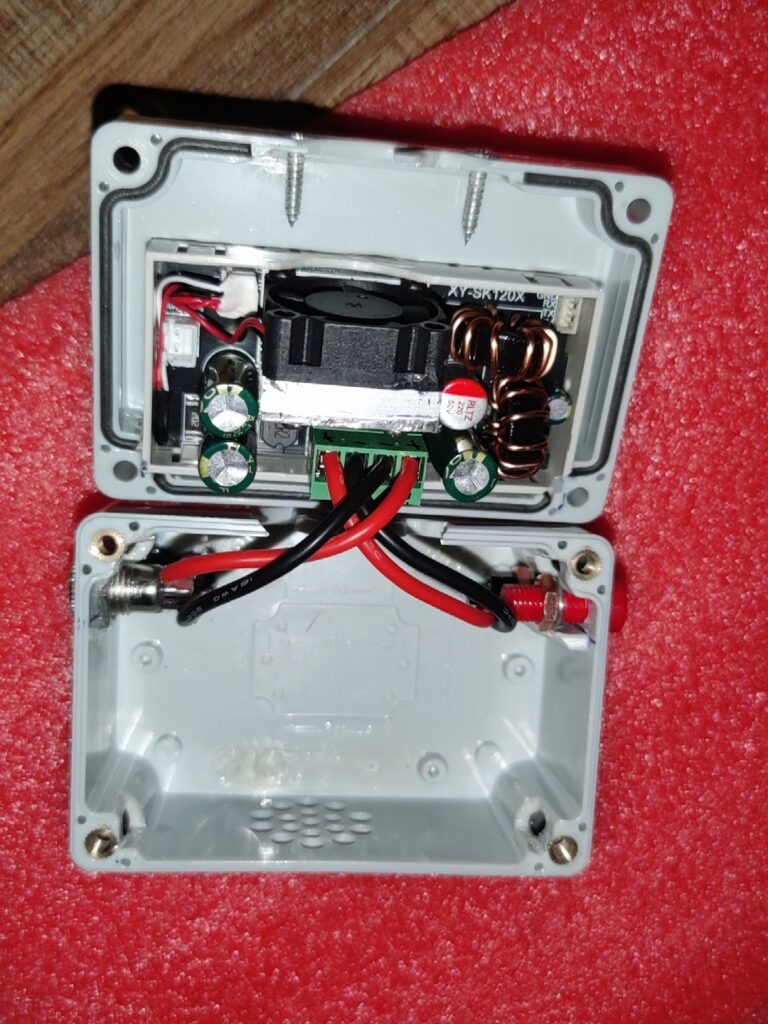

≡ 6. Customizing Junction Boxes for Niche Applications

In niche applications—whether it’s artificial intelligence, high-frequency communications, or bioengineering—custom junction boxes are often required to meet the specific needs of the industry.

- AI Integration: In AI-powered systems, junction boxes may need to accommodate high-frequency signal processing or specialized connectors. These boxes are designed with high-performance materials to prevent electromagnetic interference (EMI) and maintain signal integrity.

- Medical and Biotech Applications: In medical technology or biotech, junction boxes must be designed with antimicrobial materials und sterile enclosures to ensure the safety of sensitive equipment. They may also require tamper-proof features to ensure compliance with regulatory standards.

≡ Conclusion: The Unsung Heroes of Extreme Environments

While junction boxes are often overlooked, they play an essential role in protecting electrical components in extreme environments. Whether safeguarding against high temperatures, explosive gases, or deep-sea pressures, junction boxes are designed to withstand conditions that ordinary enclosures cannot. As industries push the boundaries of technology in fields like space exploration, subsea energy, and industrial automation, junction boxes will continue to evolve to meet new and unforeseen challenges. By enhancing the reliability and safety of electrical systems, junction boxes ensure that critical infrastructures remain safe, efficient, and functional even in the most extreme and hazardous environments.