Wartung und Inspektion von Verteilerkästen

Die Wartung und Inspektion Ihrer Verteilerkästen ist wichtig, um die Sicherheit, Funktionalität und Zuverlässigkeit Ihrer elektrischen Systeme zu gewährleisten. Mit der Zeit können Verteilerdosen beschädigt werden, korrodieren oder Staub, Schmutz und Feuchtigkeit ansammeln, was zu elektrischen Ausfällen oder Sicherheitsrisiken führen kann. Regelmäßige Wartung und Inspektion helfen dabei, potenzielle Probleme zu erkennen, bevor sie zu ernsthaften Problemen werden. Hier finden Sie einen umfassenden Leitfaden für die Wartung und Inspektion Ihrer Verteilerkästen.

≡ Bedeutung der regelmäßigen Inspektion

Regelmäßige Inspektionen sind wichtig, um sicherzustellen, dass Verteilerkästen sicher und funktionsfähig bleiben. Wenn sie nicht richtig gepflegt werden, können sie zu einer Quelle elektrischer Gefahren werden, einschließlich Kurzschlüssen, Bränden oder Stromschlägen. Inspektionen helfen bei der Erkennung von Problemen wie:

- Lose Verbindungen: Im Laufe der Zeit können sich die elektrischen Verbindungen im Inneren der Anschlussdose aufgrund von Vibrationen oder thermischer Ausdehnung lockern, was zu einem schlechten elektrischen Kontakt führt.

- Korrosion oder Rost: Vor allem in Außenbereichen oder in der Industrie können Anschlussdosen aus Metall korrodieren, was ihre Festigkeit und Sicherheit beeinträchtigen kann.

- Eindringen von Feuchtigkeit: Wasser oder Feuchtigkeit können in das Gehäuse eindringen und die elektrischen Bauteile im Inneren beschädigen oder Kurzschlüsse verursachen.

- Physische Schäden: Abzweigdosen können im Laufe der Zeit durch Stöße, Risse oder Abnutzung beschädigt werden, insbesondere in stark frequentierten Bereichen oder rauen Umgebungen.

≡ Schritte zur Wartung und Inspektion von Verteilerdosen

≡ 1. Strom abschalten

Bevor Sie mit der Inspektion oder Wartung Ihrer Anschlussdose beginnen, schalten Sie immer den Stromkreis ab, den die Dose steuert. Dadurch wird sichergestellt, dass Sie alle Arbeiten sicher und ohne das Risiko eines Stromschlags durchführen können.

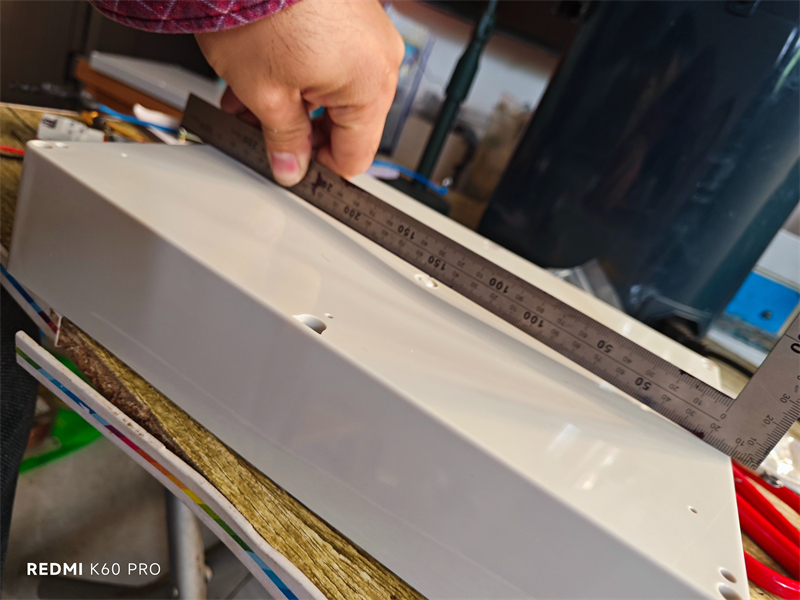

≡ 2. Prüfen Sie die Box auf physische Beschädigungen

- Visuelle Kontrolle: Untersuchen Sie die Anschlussdose auf sichtbare Anzeichen von Schäden wie Risse, Beulen oder Verschleiß. Jede physische Beschädigung könnte darauf hinweisen, dass die Dose die internen elektrischen Komponenten nicht mehr vollständig schützt.

- Prüfung der Stabilität: Vergewissern Sie sich, dass die Anschlussdose fest montiert und nicht lose ist. Eine lose Anschlussdose kann sich während des Betriebs verschieben und Spannungen in der Verkabelung verursachen, was zu elektrischen Störungen führen kann.

≡ 3. Auf Feuchtigkeit oder Schmutz untersuchen

- Feuchtigkeitskontrollen: Achten Sie auf Anzeichen von Wassereintritt oder Feuchtigkeit im Inneren des Gehäuses. Feuchtigkeit kann zu Kurzschlüssen oder Korrosion der Bauteile führen. Stellen Sie sicher, dass die Dichtung oder der O-Ring intakt ist und richtig sitzt. Wenn die Anschlussdose im Freien verwendet wird, stellen Sie sicher, dass sie ordnungsgemäß abgedichtet ist, damit kein Wasser eindringen kann.

- Schmutz oder Staub: Angesammelter Schmutz oder Staub kann den Luftstrom behindern oder zu Überhitzung führen. Reinigen Sie das Gehäuse vorsichtig mit einem trockenen Tuch oder mit Druckluft. Vermeiden Sie die Verwendung von Flüssigkeiten oder scharfen Reinigungschemikalien, da diese die elektrischen Komponenten beschädigen könnten.

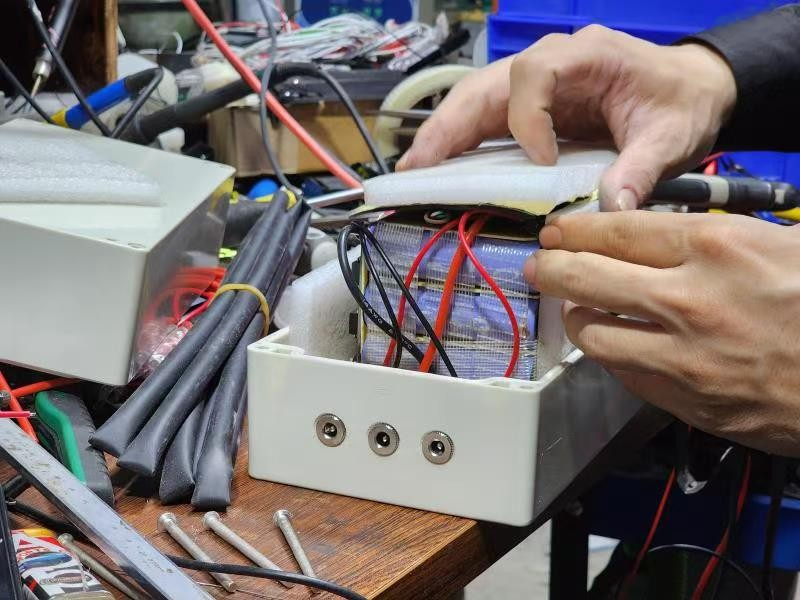

≡ 4. Prüfen Sie die elektrischen Verbindungen

- Dichtheit der Verbindungen: Prüfen Sie, ob alle elektrischen Anschlüsse im Inneren der Anschlussdose fest und sicher sind. Lose Verbindungen können zu Lichtbogenbildung, Überhitzung oder sogar Brandgefahr führen. Wenn Sie lockere Schrauben oder Klemmen feststellen, ziehen Sie sie mit dem entsprechenden Werkzeug fest.

- Prüfen Sie auf Anzeichen von Überhitzung: Achten Sie auf verfärbte Drähte, verbrannte Isolierung oder Anzeichen von Überhitzung. Dies könnte auf übermäßigen Strom, schlechte Verbindungen oder eine fehlerhafte Verkabelung hinweisen.

- Korrosion: Prüfen Sie bei Metalldosen auf Anzeichen von Korrosion an den Drähten oder Klemmen. Falls Korrosion vorhanden ist, muss sie möglicherweise entfernt oder ersetzt werden, um die Sicherheit der Dose zu gewährleisten.

≡ 5. Dichtungen und Dichtungsringe prüfen

- Integrität des Siegels: Wenn Ihre Anschlussdose für die Verwendung im Freien ausgelegt ist (IP65 oder höher), überprüfen Sie, ob die Dichtung um den Deckel intakt und nicht abgenutzt ist. Eine beschädigte Dichtung kann das Eindringen von Staub, Wasser oder anderen Verunreinigungen ermöglichen, was die Wirksamkeit der Dose beeinträchtigt.

- Beschädigte Dichtungen austauschen: Wenn die Dichtung gerissen oder beschädigt ist, ersetzen Sie sie durch eine neue Dichtung aus dem gleichen Material und in der gleichen Größe, um die Wasser- und Staubdichtigkeit wiederherzustellen.

≡ 6. Suchen Sie nach überlasteten Stromkreisen

- Belastung des Stromkreises prüfen: Stellen Sie sicher, dass die Stromkreise in der Anschlussdose nicht überlastet sind. Ein überlasteter Stromkreis kann zu Überhitzung führen und ein Brandrisiko darstellen. Vergewissern Sie sich, dass die Drähte und Stecker in der Anschlussdose für die richtige Stromstärke und Spannung ausgelegt sind.

- Überprüfen Sie Sicherungen oder Unterbrecher: Wenn Ihr Verteilerkasten Sicherungen oder Schutzschalter enthält, prüfen Sie, ob diese ordnungsgemäß funktionieren und nicht ausgelöst oder durchgebrannt sind. Ersetzen Sie defekte Sicherungen oder setzen Sie Schutzschalter nach Bedarf zurück.

≡ 7. Richtige Erdung sicherstellen

- Erdung überprüfen: Eine ordnungsgemäße Erdung ist für die Sicherheit unerlässlich. Stellen Sie sicher, dass alle Erdungsanschlüsse sicher und intakt sind. Eine lockere oder fehlende Erdung kann zu einem elektrischen Schlag führen oder andere Probleme im elektrischen System verursachen.

- Prüfen Sie die Erdungsanschlüsse auf Korrosion: Genau wie die elektrischen Anschlüsse können auch die Erdungsanschlüsse im Laufe der Zeit korrodieren, insbesondere in Außenbereichen. Stellen Sie sicher, dass die Erdungsschrauben und -klemmen korrosionsfrei sind.

≡ 8. Dokumentieren Sie Ihre Befunde

Dokumentieren Sie nach der Inspektion des Verteilerkastens alle Feststellungen, Reparaturen oder durchgeführten Wartungsarbeiten. Diese Dokumentation kann helfen, den Zustand und die Historie des Kastens zu verfolgen, was besonders für regelmäßige Wartungspläne wichtig ist.

≡ Wie oft sollten Abzweigkästen inspiziert werden?

Die Häufigkeit der Inspektionen von Verteilerkästen hängt von mehreren Faktoren ab, darunter die Umgebung, in der sich der Kasten befindet, die Kritikalität des elektrischen Systems und das Alter des Kastens. Hier sind einige allgemeine Richtlinien:

- Im Freien oder in industriellen Umgebungen: In rauen Umgebungen, in denen sie häufig Feuchtigkeit, Staub oder Chemikalien ausgesetzt sind, sollten die Anschlussdosen mindestens alle 6 Monate überprüft werden.

- Installationen in Innenräumen: Bei Installationen in kontrollierten Innenräumen, wie z. B. in Büros oder Wohnungen, können die Inspektionen jährlich oder alle zwei Jahre durchgeführt werden.

- Kritische elektrische Systeme: Bei kritischen Systemen, wie z. B. in medizinischen Einrichtungen oder Industriemaschinen, können häufigere Inspektionen erforderlich sein - alle 3 bis 6 Monate.

≡ Allgemeine Probleme und Fehlerbehebung

- Eindringen von Wasser oder Feuchtigkeit: Wenn Sie Wasser im Inneren der Anschlussdose feststellen, ist die Dichtung möglicherweise beschädigt. Vergewissern Sie sich, dass die Dose richtig abgedichtet ist, und untersuchen Sie die Umgebung auf undichte Stellen.

- Überhitzung: Überhitzung kann durch lose Verbindungen, zu hohe Ströme oder schlechte Belüftung verursacht werden. Ziehen Sie die Anschlüsse fest und prüfen Sie die Leistung der Kabel und Stecker.

- Korrodierte Klemmen: Wenn die Klemmen korrodiert sind, reinigen Sie sie mit einem geeigneten Reinigungsmittel oder ersetzen Sie sie gegebenenfalls.

≡ Schlussfolgerung

Regelmäßige Wartung und Inspektion von Verteilerkästen sind unerlässlich, um die Sicherheit, Leistung und Langlebigkeit Ihres elektrischen Systems zu gewährleisten. Wenn Sie die oben beschriebenen Schritte befolgen, können Sie potenzielle Probleme frühzeitig erkennen, Sicherheitsrisiken vermeiden und die Lebensdauer Ihrer Verteilerkästen verlängern. Denken Sie immer daran, die Sicherheitsvorschriften zu befolgen, und wenden Sie sich im Zweifelsfall an einen professionellen Elektriker, der Sie bei Reparaturen oder komplexen Problemen unterstützt.

Dieser Leitfaden bietet einen umfassenden Ansatz für die Wartung und Inspektion von Verteilerkästen, um sicherzustellen, dass elektrische Systeme über Jahre hinweg sicher und zuverlässig bleiben.