HIGHYI ALuminum Junction Enclosure

Compared to other electrical enclosure, Aluminum made boxes will have more advantages

I. Material

- Good Conductivity

- Strong Corrosion Resistance

- Lightweight and Sturdy

II. Design

- Accurate Adaptation

- Reasonable Layout

- Convenient Opening and Closing

III. Protection Performance

- Waterproof and Dustproof

- Electromagnetic Shielding

IV. Others

- Aesthetic Appearance

- High Durability

HIGHYI ELEKTRISCH

Wasserdichtes Elektrisches,Elektrischer Steckverbinder,Elektrische Schutzprodukte Lieferant

Highyi’s aluminum junction enclosure is a key component in electrical systems.

Construction and Material

- Made of aluminum, which offers a good combination of strength and lightweight properties.

- The aluminum construction provides durability to protect the internal contents.

Funktion

- Its primary role is to house and safeguard electrical junctions.

- These are the points where electrical wires are connected, and the aluminum enclosure prevents accidental human contact with live parts, reducing the risk of electrical shock.

- It also shields the junctions from environmental factors such as dust, moisture, and dirt. This protection is crucial for maintaining the proper functioning of the electrical connections over time.

Features

- Often has proper sealing to keep out moisture and dust, typically using rubber gaskets.

- Designed for easy access, with hinged doors or removable panels, facilitating installation, maintenance, and inspection of the junctions inside.

- Comes with mounting options like holes or brackets for attaching it to walls, poles, or other structures.

- Some enclosures may have ventilation to allow for heat dissipation if there are components inside that generate heat during operation.

Applications

- Widely used in industrial settings such as factories and power plants to protect the numerous electrical junctions in complex electrical systems.

- In commercial buildings, it safeguards junctions in the building’s electrical distribution systems for lighting, power outlets, etc.

- Also commonly employed in outdoor installations like street lighting systems, telecommunications towers, and solar power installations to protect against the elements and potential vandalism. In summary, the aluminum junction enclosure is an essential element for ensuring the safety and reliable operation of electrical junctions in various environments.

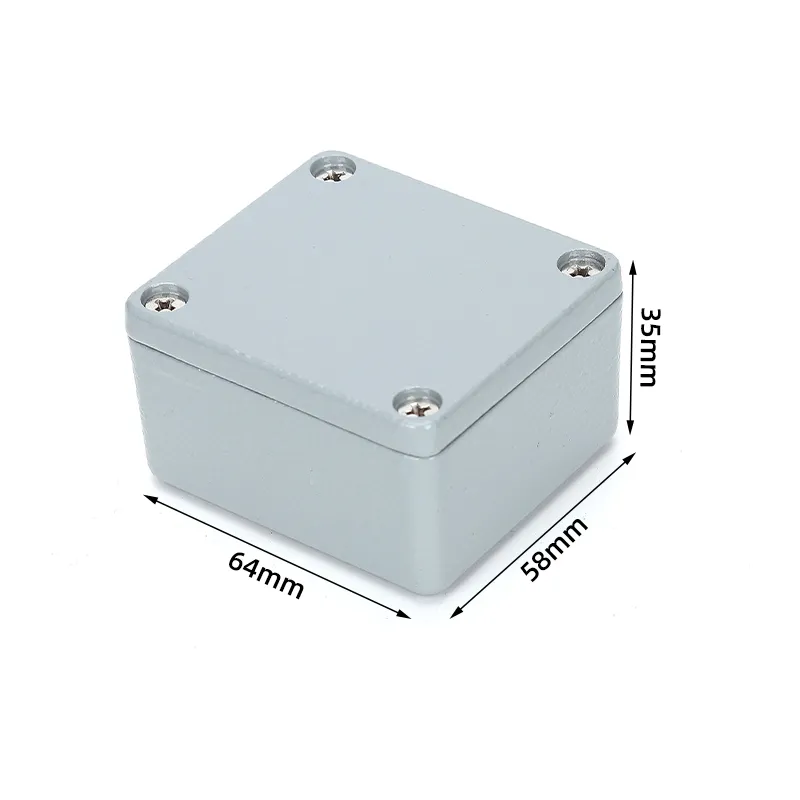

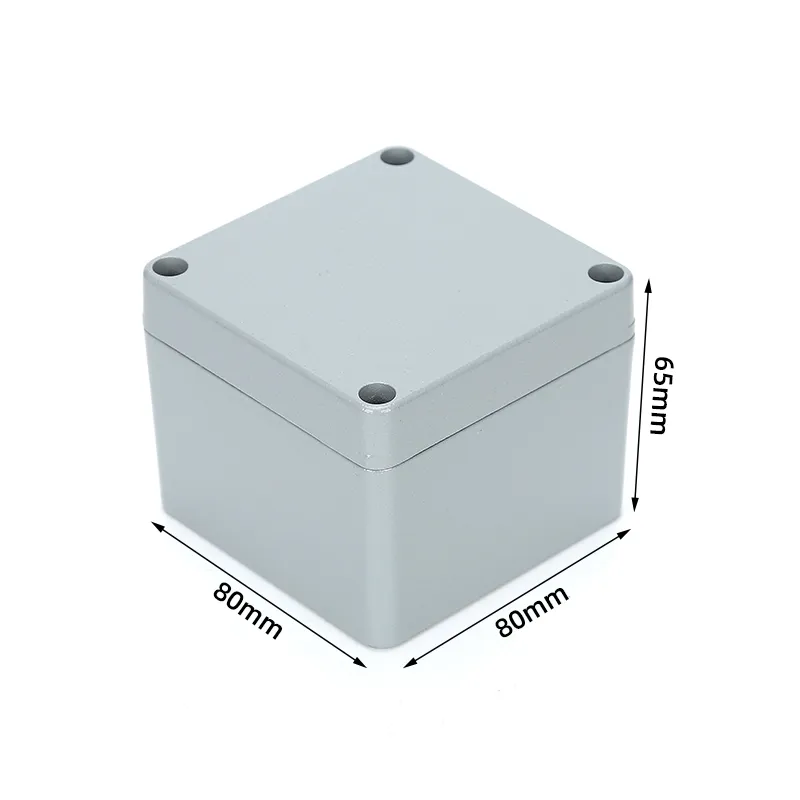

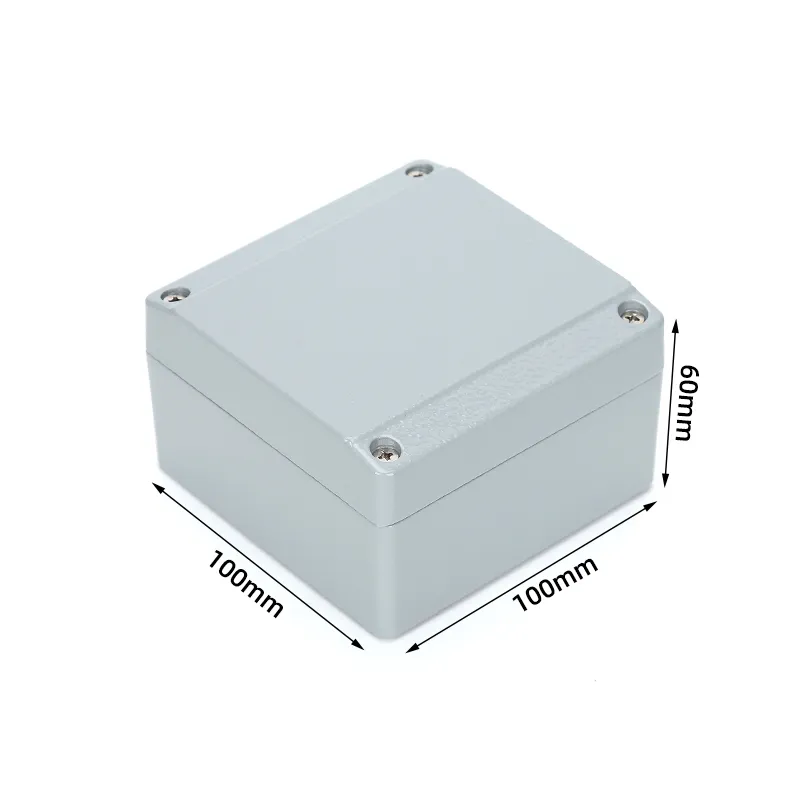

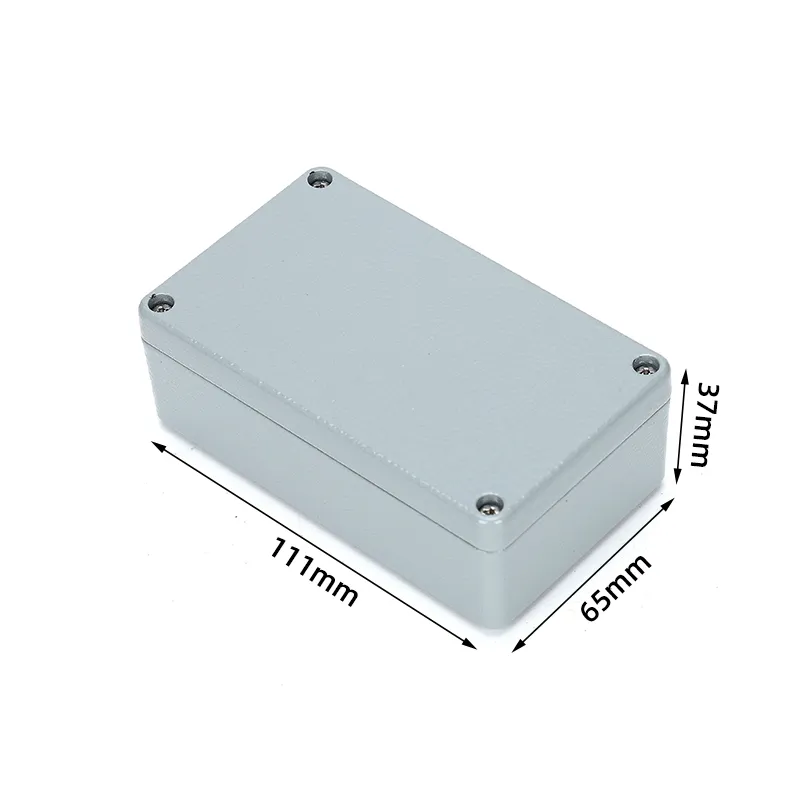

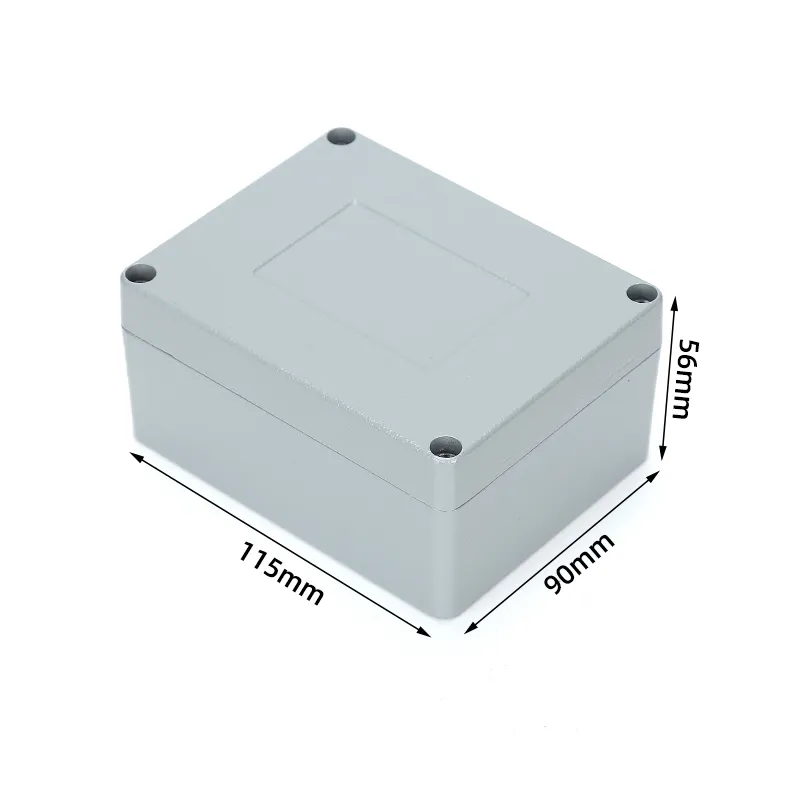

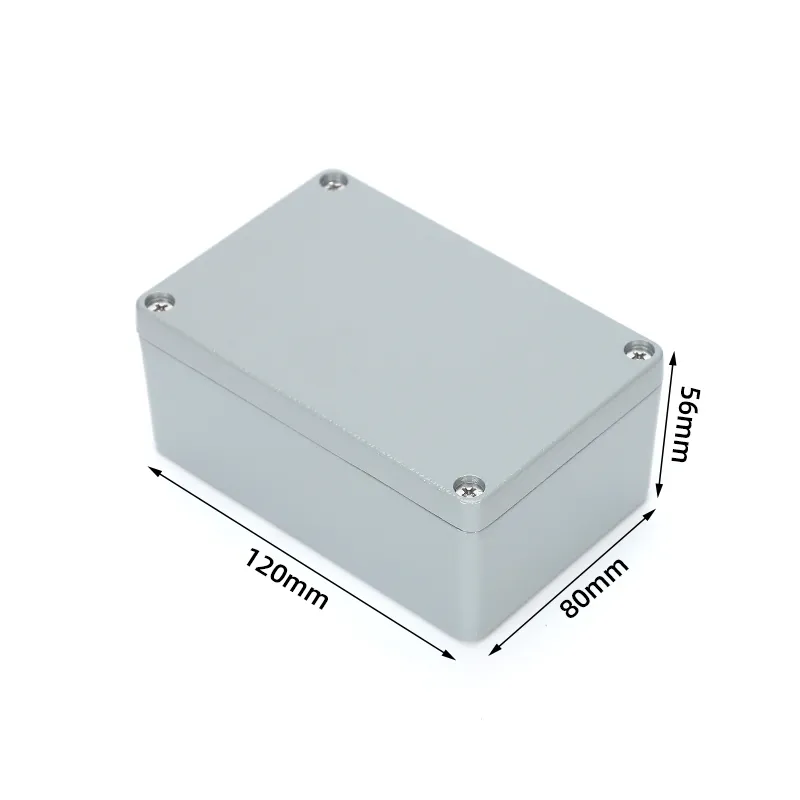

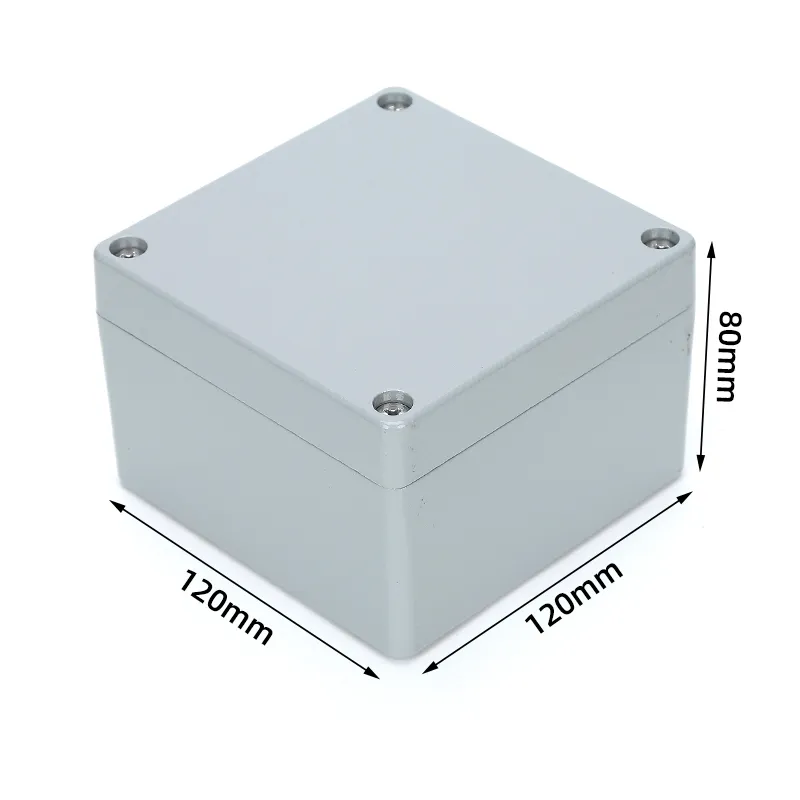

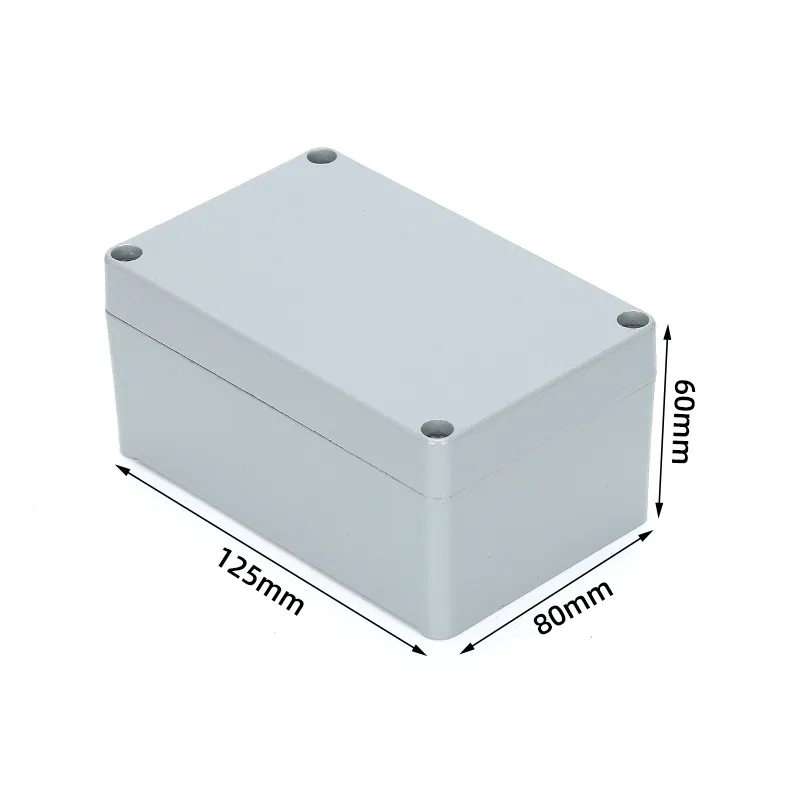

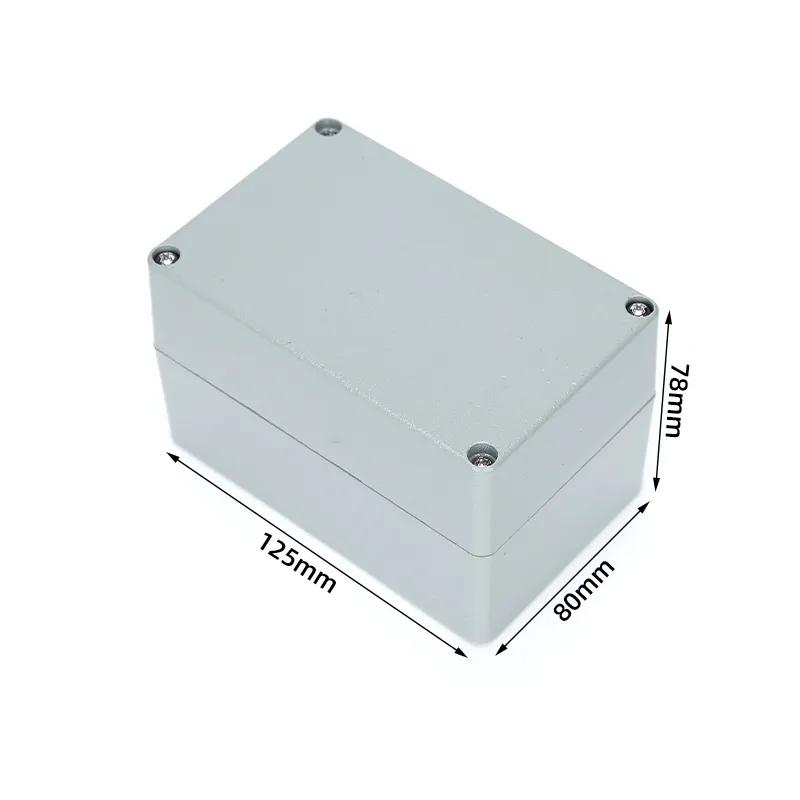

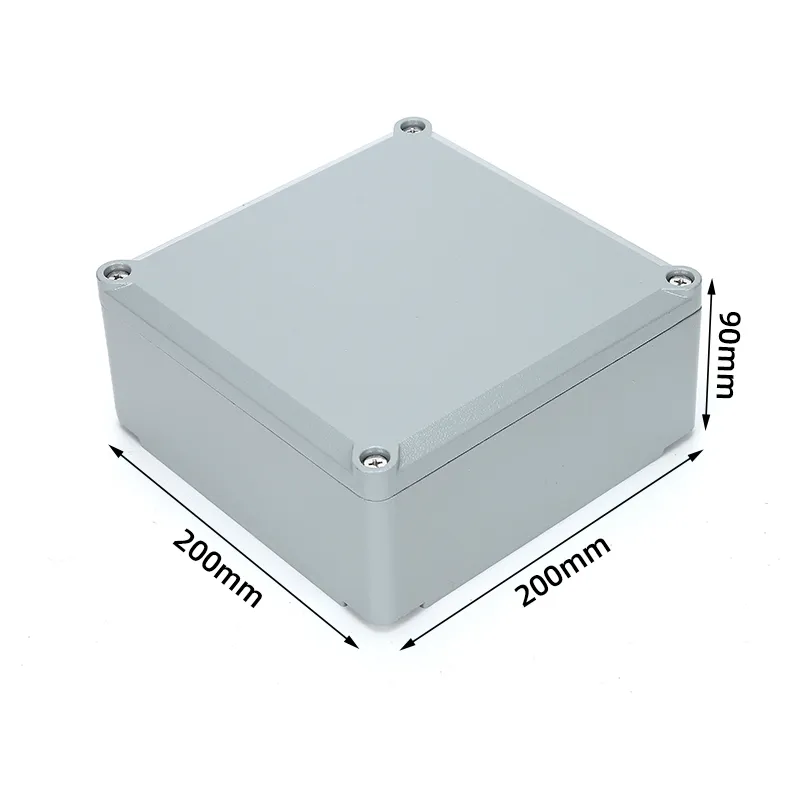

Standard Grey Aluminum Enclosure / Box

Colorful Aluminum Enclosure / Box

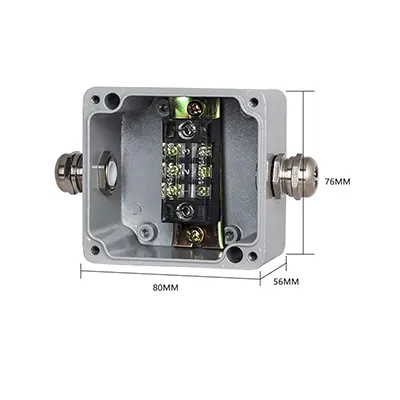

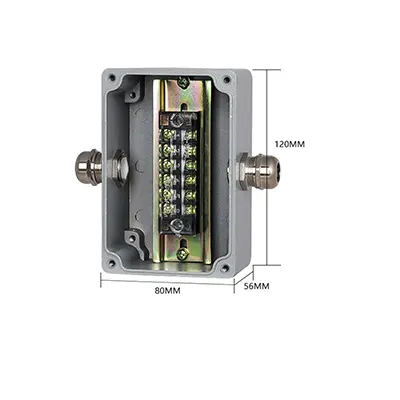

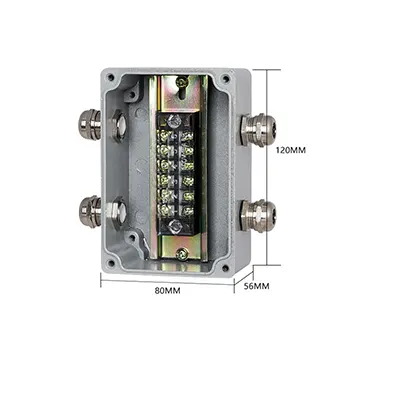

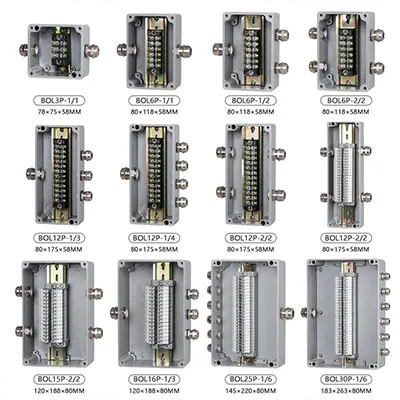

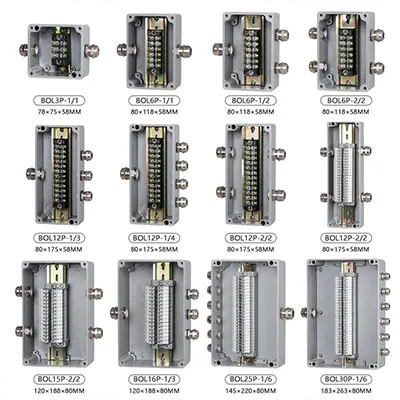

Terminal Block Aluminum Enclosure / Box

ALUMINUM ENCLOSURE SOLUTION AT HIGHYI ELECTRIC

Wasserdichtes Elektrisches,Elektrischer Steckverbinder,Elektrische Schutzprodukte Lieferant

We’re a leading Aluminum Junction Enclosure manufacturer in China because we’re excellent.

When you choose our products, you’re not just a business deal.

We consider clients as partners and are committed to providing great service for your benefit.

Our Aluminum Junction Enclosure is both aesthetically pleasing and high – quality and durable.

You don’t have to choose between design and quality as you can have both.

Each enclosure is made following strict quality protocols. We ensure every component meets our high standards. This is our commitment.

Use our Aluminum Junction Enclosure to boost your business with reliable performance. Partner with a trustworthy manufacturer. Contact us.

Why use Aluminum Junction box?

Aluminum junction boxes are used because:

- Durability They can endure harsh outdoor and industrial conditions, remaining functional over time.

- Electrical Conductivity Aluminum is a good conductor, ensuring stable current flow and minimizing energy losses in circuits.

- Lightweight It’s easy to transport, position, and install, reducing strain on workers and installation time/costs.

- Heat Dissipation Good heat – dissipating properties keep components within a safe temperature range in applications like data centers.

- Corrosion Resistance The natural oxide layer and possible additional treatments protect against corrosion in humid environments.

- Customizability They can be made in different shapes, sizes, and with various mounting options for specific needs.

- Cost – effectiveness Their durability and other advantages minimize long – term maintenance and replacement costs.

How to choose Aluminum Junction box?

When choosing an aluminum junction box, consider the following:

- Size and Capacity : Ensure the box has enough internal space for components and an appropriate number of entry/exit points for wires based on your circuit needs.

- Environmental Conditions – Check its ability to withstand the temperature range, have good moisture resistance (look at IP ratings), and corrosion resistance (consider anodized or coated options for harsh environments).

- Electrical Requirements – Verify that the voltage and current ratings are suitable for your application and that there are proper grounding provisions.

- Mounting and Installation – Select a box with suitable mounting options and features that make installation and maintenance easy.

- Cost and Quality – Balance price with quality. Research the manufacturer’s reputation and look for relevant certifications.

How to Install Aluminum Junction Box?

Here are some tips for installation

- Gather Tools and Materials: Get drill, screwdrivers, tape measure, level, wire strippers, pliers, screws, anchors, wire nuts, terminals, and conduits if needed.

- Check the Box: Inspect for damages and check knock – out holes and size.

- Plan the Location: Consider access, proximity to power source and devices, and environmental protection.

- Mark the Mounting Holes: Use tape measure and level to mark positions on the mounting surface.

- Drill Pilot Holes (if necessary): Based on the surface type, drill and insert anchors if needed.

- Mount the Box: Align and secure the box with screws, checking it’s level.

- Connect the Wires: Insert wire ends into terminals (using wire nuts or screw – type terminals), following wiring diagrams and color – coding.

- Route the Wires: Organize wires inside the box, use conduits if needed, and ensure orderly entry and exit.

HIGHYI ELETRIC