HIGHYI Plastic Junction Box/Enclosure

Plastic Junction Box is the leading product in our company. We are a professional manufacturer and wholesale supplier in China.

We can produce Plastic Junction Boxes in various specifications and designs.

No matter if you are looking for a Plastic Junction Box supplier or if you need custom-made ones, we can all help. Send inquiry to get an instant quote now!

ABS Junction Box

Polycarbonate Junction Box

Customized Hole Box

HIGHYI Plastic Junction Box/Enclosure

Our Plastic Junction Boxes/Enclosures are crafted with high-quality plastic materials, ensuring excellent durability and reliable performance. They come in a wide range of sizes, shapes and configurations to meet diverse application requirements. Whether you’re in search of a standard Plastic Junction Box/Enclosure supplier or have specific needs for custom-made ones, we’ve got you covered.

Main series include:

AG/AT, PG/PT (A : ABS, P: Polycarbonate, G: Grey lid, T: Transparent)

FG/FT (F: short name for Chinese waterproof box name: “fangshuihe”.G: Grey lid, T: Transparent)

BG/BT,KG/KT (B: Stainless Steel Buckle K: Plastic Buckle.G: Grey lid, T: Transparent)

I. Material

- ABS

- Polycarbonate(PC)

- بولي كلوريد الفينيل

II. Design

- Separated Lid Type

- Hinged Lid Type

III. Protection Performance

- IP 55/65/IP67

- Electromagnetic Shielding

IV. Others

- Aesthetic Appearance

- High Durability

هاي هاي إلكتريك

كهربائي مقاوم للماء، موصل كهربائي، موصل كهربائي، مورد منتجات الحماية الكهربائية

Highyi’s plastic junction enclosure is a key component in electrical systems.And It has many advantages

Cost-effective

- Low material cost: Plastic is generally less expensive than metal, making plastic junction boxes a more budget-friendly option, especially for large-scale installations or projects with cost constraints.

- Reduced installation cost: They are often lighter in weight than their metal counterparts, which can make handling and installation quicker and easier, potentially reducing labor costs. Additionally, some plastic junction boxes come with integrated features like cable clamps, eliminating the need for additional clamping accessories and further saving on costs.

Safety

- Electrical insulation: Plastic is a non-conductive material, which means that plastic junction boxes do not conduct electricity. This provides an extra layer of safety by reducing the risk of electrical shock, especially in situations where the box may be accidentally touched or exposed.

- No grounding required: Since they are non-conductive, plastic junction boxes typically do not need to be grounded, simplifying the installation process compared to metal boxes, which usually require a ground connection.

Durability

- Corrosion resistance: Plastic is highly resistant to corrosion, making plastic junction boxes suitable for use in a variety of environments, including those with high humidity, exposure to chemicals, or outdoor conditions where metal boxes may rust over time.

- Impact resistance: Many plastics used in junction boxes, such as ABS and polycarbonate, have good impact resistance, which means they can withstand bumps, knocks, and other physical impacts without breaking or cracking easily. This helps to protect the electrical components inside the box.

- UV resistance: Some plastics are formulated with UV stabilizers, which make them resistant to the harmful effects of ultraviolet (UV) radiation from the sun. This is particularly important for outdoor applications, as it helps prevent the plastic from deteriorating, fading, or becoming brittle due to prolonged exposure to sunlight.

Design flexibility

- Versatile shapes and sizes: Plastic can be molded into a wide range of shapes and sizes, allowing for greater design flexibility to meet the specific requirements of different applications. This means that plastic junction boxes can be customized to fit into tight spaces or to accommodate complex wiring configurations.

- Color options: Plastic junction boxes are available in various colors, which can be useful for color-coding or for matching the aesthetic of the surrounding environment. This is in contrast to metal boxes, which usually have a limited range of finishes or may require additional painting or coating to achieve a desired color.

- الشفافية: Some plastic materials, such as clear polycarbonate, offer transparency, which can be beneficial for visual inspection of the internal components or for applications where it is necessary to see the wiring or connections inside the box without having to open it.

Ease of installation

- Simple mounting: Plastic junction boxes are typically easy to mount on walls, ceilings, or other surfaces. They may come with pre-drilled holes or built-in mounting brackets, making it straightforward to attach them using screws, nails, or other common fastening methods.

- Snap-on or clip-on features: Some plastic boxes have snap-on or clip-on covers or accessories, which can be quickly and easily attached or removed without the need for tools. This simplifies the process of accessing the internal wiring for maintenance or modifications.

- Compatibility with different cables: Plastic junction boxes can be designed to accommodate a variety of cable types and sizes, with features like cable entry points, grommets, or cable clamps that help to secure and organize the cables neatly inside the box.

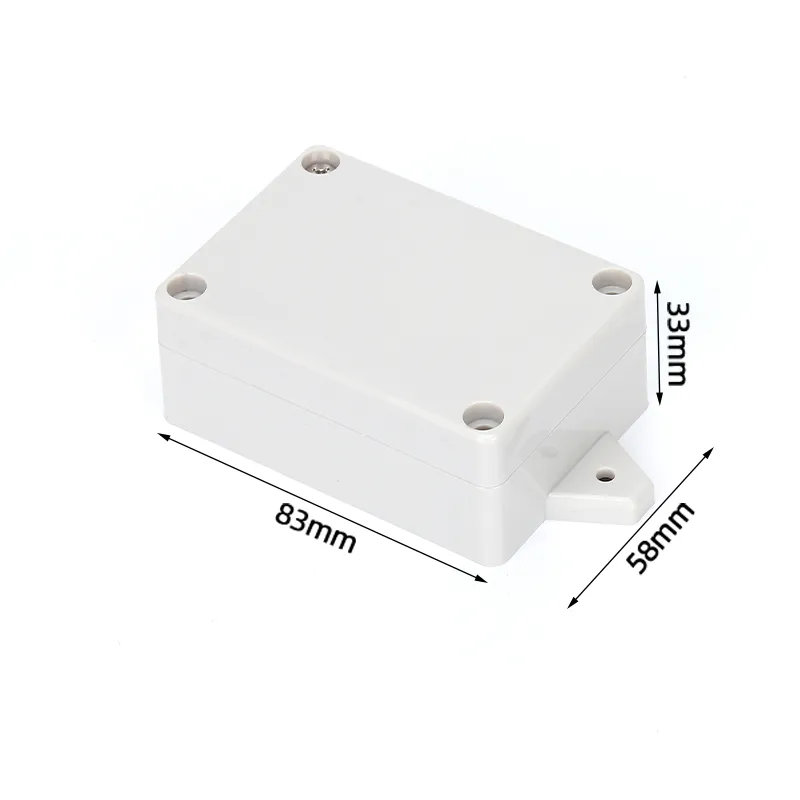

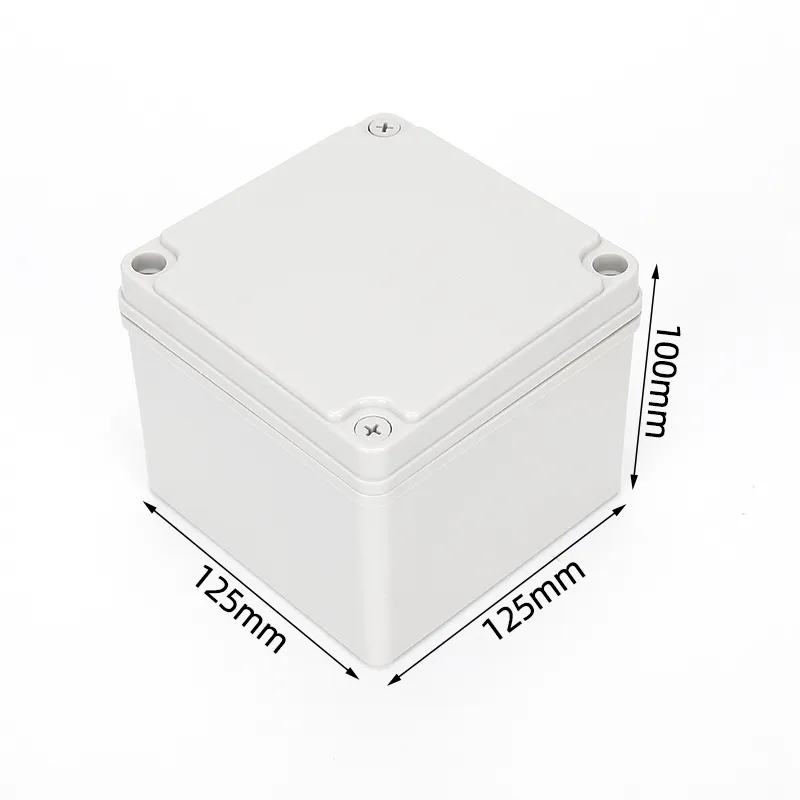

F Series Standard Grey Plastic Enclosure / Box

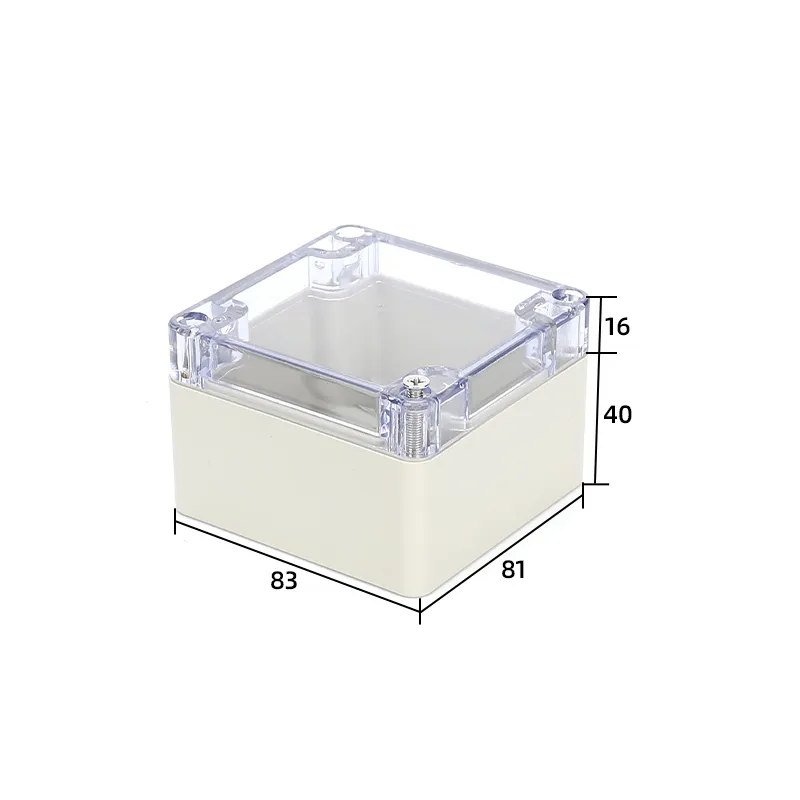

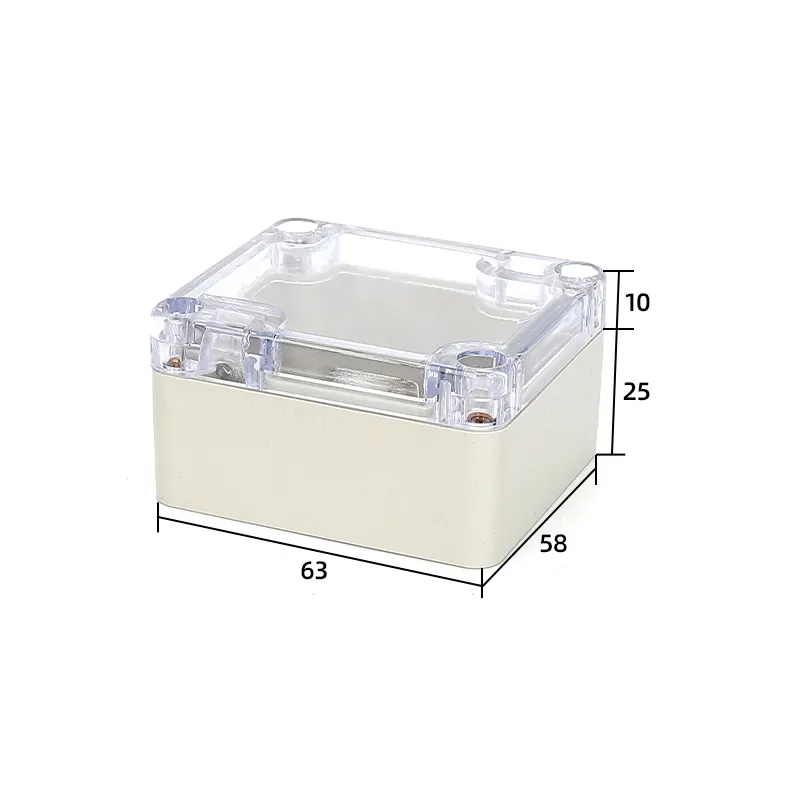

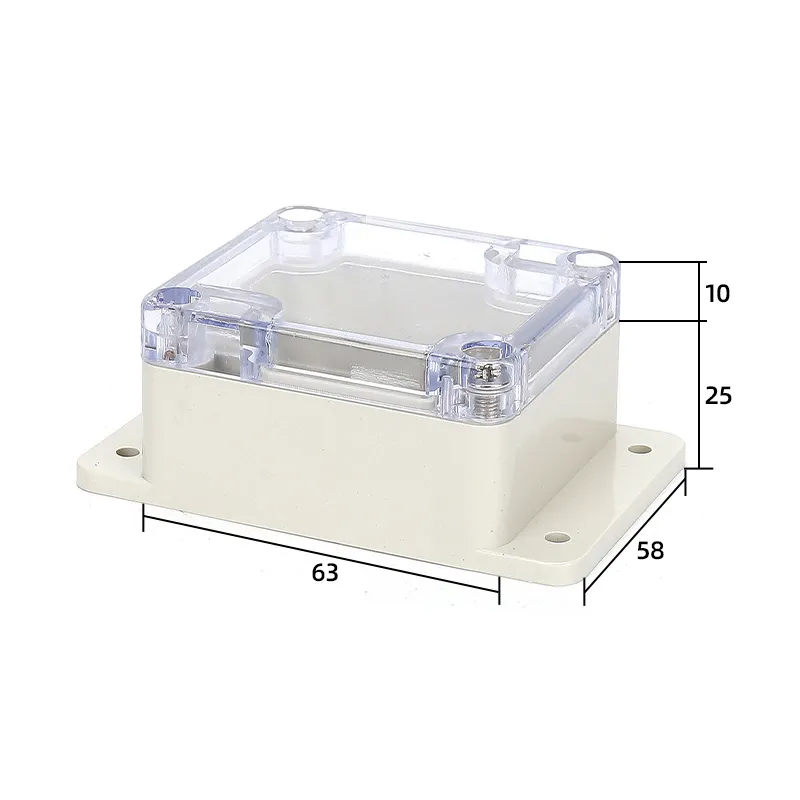

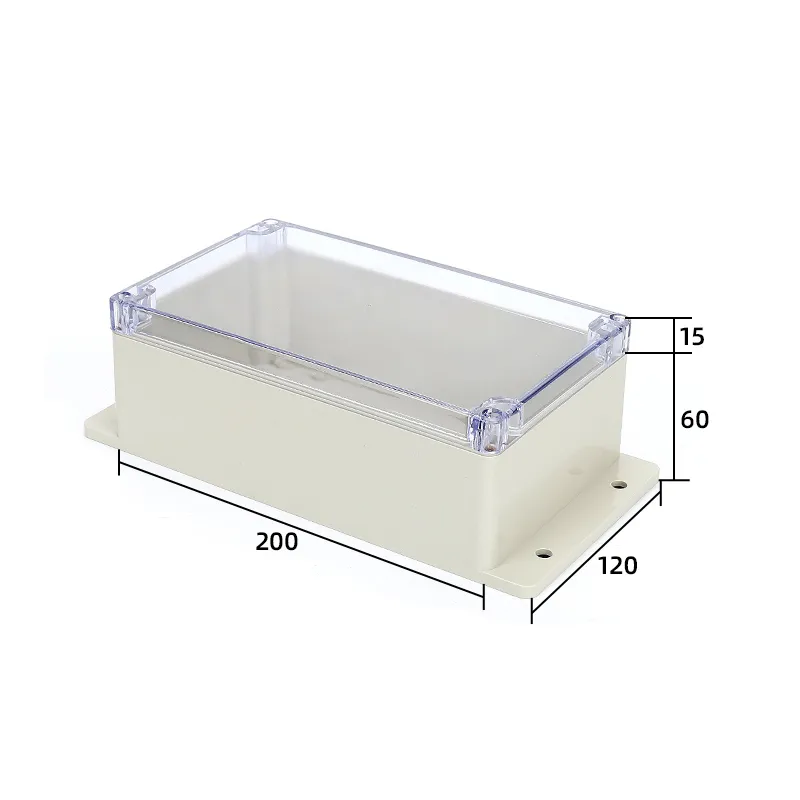

AG AT Series ABS Plastic Junction Enclosure / Box

Customized Plastic Enclosure / Box

PLASTIC ENCLOSURE SOLUTION AT HIGHYI ELECTRIC

كهربائي مقاوم للماء، موصل كهربائي، موصل كهربائي، مورد منتجات الحماية الكهربائية

We’re a leading PLASTIC BOX manufacturer in China due to our excellence.

When you choose our products, it’s far more than just a business transaction.

We regard clients as partners and are dedicated to offering excellent service for your advantage.

Our PLASTIC BOX is both visually appealing and of high quality and durability.

You don’t need to make a choice between design and quality as you can enjoy both.

Each box is manufactured in accordance with strict quality procedures.

We guarantee that every component complies with our high standards. This is our commitment.

Utilize our PLASTIC BOX to enhance your business with reliable performance. Partner with a trustworthy manufacturer. Contact us.

Why use Plastic Junction box?

There are multiple reasons to use plastic junction boxes:

- Durability: Made of quality materials, resistant to corrosion and can endure various conditions, ensuring a long lifespan.

- Cost-Effective: Generally more affordable than some alternatives while maintaining good performance to cut project costs.

- Safety: As an insulator, it reduces the risk of electrical shock by preventing contact between conductors and external objects.

- Ease of Installation: Lightweight and easy to handle, modify as needed during installation, saving time and effort.

- Design Flexibility: Available in diverse shapes, sizes and designs to fit different electrical setups.

- Chemical Resistance: Can resist common chemicals, maintaining functionality in various environments.

How to choose Plastic Junction box?

When choosing a plastic junction box:

- Check the material quality: preferring durable plastics like ABS or PVC.

- Consider the size and capacity: to fit your electrical components properly.

- Look at the IP rating: based on the usage environment.

- Determine suitable mounting options for installation.

- Verify relevant certifications for safety and quality.

- Opt for a design that enables easy access and maintenance.

- Ensure compatibility with other electrical components.

How to Install Junction Box?

- Gather Tools and Materials: Get drill, screwdrivers, tape measure, level, wire strippers, pliers, screws, anchors, wire nuts, terminals, and conduits if needed.

- Check the Box: Inspect for damages and check knock – out holes and size.

- Plan the Location: Consider access, proximity to power source and devices, and environmental protection.

- Drill Pilot Holes (if necessary): Based on the surface type, drill and insert anchors if needed.

- Mount the Box: Align and secure the box with screws, checking it’s level.

- Connect the Wires: Insert wire ends into terminals (using wire nuts or screw – type terminals), following wiring diagrams and color – coding.

- Route the Wires: Organize wires inside the box, use conduits if needed, and ensure orderly entry and exit.

HIGHYI ELETRIC